A deep dive into cutting-edge welding and cutting solutions at the Beijing Essen Fair.

Navigating Innovation: The Beijing Essen Welding & Cutting Fair and the Future of Fabrication

The Beijing Essen Welding & Cutting Fair stands as a paramount international event, a vibrant crucible where the latest advancements in welding, cutting, and fabrication technologies converge. Far more than just an exhibition, it’s a pivotal platform that fosters international trade, facilitates crucial industry networking, and offers an unparalleled showcase for groundbreaking innovations. For B2B decision-makers in sectors ranging from automotive and construction to shipbuilding and heavy machinery, this fair is an indispensable compass, guiding strategic investments and highlighting the future trajectory of manufacturing excellence. Specifically, for the heat fusion machine and Hot cutting pipe machine industries, the Beijing Essen Fair provides a unique lens through which to view product evolution, assess competitive landscapes, and forge partnerships that drive efficiency and profitability.

In today’s highly competitive global market, the demand for higher precision, greater operational efficiency, and unwavering reliability from industrial equipment is non-negotiable. The evolution of heat fusion machines and Hot cutting pipe machines is therefore critical, as these tools form the backbone of numerous industrial processes. Exhibitors at the fair demonstrate how their cutting-edge solutions address these intricate demands, pushing the boundaries of what’s possible in material joining and separation. From sophisticated automated systems designed to enhance throughput and consistency to innovations in material science that improve durability and performance, the Beijing Essen Fair is a compelling testament to the industry’s relentless pursuit of perfection and its commitment to meeting future industrial challenges head-on.

Industry Trend Spotlight: The Digital & Automated Revolution in Welding & Cutting

The welding and cutting industry is experiencing a profound and rapid transformation, driven by a confluence of technological innovations that are fundamentally redefining operational paradigms across the globe. International attention is increasingly centered on several key trends that promise to reshape manufacturing for decades to come:

- Integration of AI and Machine Learning for Predictive Maintenance: Smart systems are revolutionizing equipment management. By leveraging artificial intelligence and machine learning algorithms, modern heat fusion machines and Hot cutting pipe machines are now capable of analyzing vast amounts of real-time operational data. This allows them to anticipate potential equipment failures, optimize maintenance schedules proactively, and significantly reduce unplanned downtime. This paradigm shift from reactive to predictive maintenance ensures continuous operation, maximizes asset utilization, and extends the overall lifespan of valuable industrial machinery.

- Advancements in Laser Welding and Cutting for Precision Applications: Laser technology continues its exponential evolution, offering unparalleled precision, blistering speed, and remarkable versatility for even the most intricate and demanding tasks. This is particularly crucial for industries that demand immaculate finishes, minimal heat-affected zones, and absolute material integrity, such as aerospace, medical device manufacturing, and high-tech electronics production. The ability to work with a diverse range of materials with such fine control is a game-changer.

- Development of Lighter and More Portable Industrial Equipment: The contemporary industrial landscape increasingly demands agile, flexible, and easily deployable solutions. This trend is particularly evident in the rising demand for more portable and compact industrial equipment, crucial for on-site construction, rapid repair operations, and remote field deployments. Manufacturers are responding by engineering innovative units that are not only lighter and more mobile but also maintain high performance and robust functionality, enabling greater operational flexibility without compromise.

- Enhanced Automation Features for Improved Productivity and Safety: The integration of robotics and advanced automation features is rapidly becoming a standard across the industry. This shift aims to reduce reliance on manual labor for repetitive, hazardous, or physically demanding tasks. Automation not only leads to a substantial boost in production output and consistency but also significantly enhances workplace safety by minimizing human exposure to dangerous environments and reducing the potential for human error – a critical consideration for any forward-thinking B2B operation.

The global welding and cutting equipment market is projected for steady and robust growth, a trajectory driven by increasing demand across pivotal sectors such as automotive, construction, and heavy manufacturing. This expansion is further propelled by the rising adoption of automated solutions, which are effectively addressing persistent labor shortages and simultaneously enhancing overall operational efficiency. Moreover, digitalization and green manufacturing initiatives are not merely theoretical concepts; they are powerful forces actively shaping market expansion. These initiatives are driving the development and adoption of more energy-efficient, environmentally responsible, and digitally integrated solutions across the entire value chain, fostering a more sustainable and intelligent future for the industry.

Emerging focus areas include the rapid deployment of automation and robotics in welding processes, the strong push for energy-efficient and intelligent manufacturing solutions, continuous innovation in advanced material processing techniques, and comprehensive digital integration across all fabrication processes. These interconnected trends collectively underscore a definitive shift towards smarter, more sustainable, and highly productive industrial ecosystems, laying the groundwork for the next generation of manufacturing capabilities.

Profiles of Leading Innovators in Welding & Cutting Technology

The Beijing Essen Welding & Cutting Fair consistently attracts the industry’s titans and trailblazers, from established global conglomerates to agile, innovative manufacturers. While international players often set global benchmarks, Chinese manufacturers are rapidly gaining ground, offering a potent combination of high-quality, cost-effective, and technologically advanced solutions that are increasingly competitive on the world stage.

HEBEI MINGMAI TECHNOLOGY CO., LTD. (MMTECHWELD)

A prominent force in the dynamic Chinese manufacturing landscape, HEBEI MINGMAI TECHNOLOGY CO., LTD. (MMTECHWELD) stands out for its unwavering commitment to technological innovation and manufacturing excellence. MMTECHWELD offers a truly comprehensive product portfolio designed to meet the diverse and exacting needs of modern industrial applications. Their extensive range includes robust MMA (Manual Metal Arc) welders, versatile MIG (Metal Inert Gas) machines, precision TIG (Tungsten Inert Gas) welders, and powerful Plasma Cutters, catering to a wide spectrum of welding and cutting requirements.

MMTECHWELD’s core strength lies in its exceptional ability to seamlessly combine cutting-edge Research & Development with highly efficient and optimized production processes. This synergistic approach results in the creation of highly competitive products that consistently deliver exceptional performance and reliability. They possess strong capabilities in serving both burgeoning domestic markets and demanding international industrial sectors, providing advanced solutions that skillfully balance sophisticated features with an attractive and cost-effective structure. For businesses seeking reliable, high-performing heat fusion machines and Hot cutting pipe machines, MMTECHWELD’s offerings present a compelling and strategic proposition.

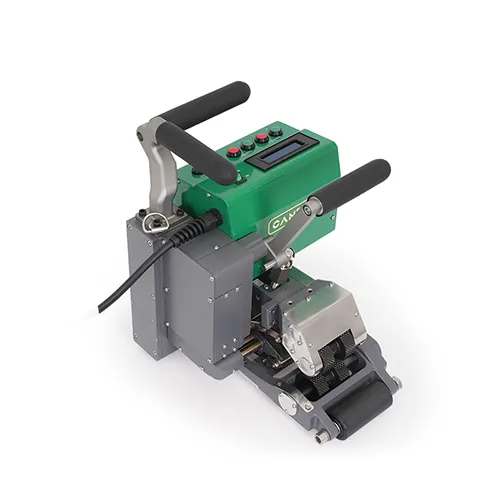

One of their flagship products, the CX600 Hot Wedge Machine, perfectly exemplifies MMTECHWELD’s dedication to precision, efficiency, and robust construction in heat fusion applications. This advanced machine is meticulously engineered for robust and consistent performance in the most demanding environments, making it crucial for critical applications such as geomembrane welding in civil engineering projects, industrial lining installations, and various environmental containment solutions. Its unparalleled reliability, coupled with advanced temperature and speed control systems, positions the CX600 Hot Wedge Machine as an essential tool for ensuring strong, durable, and absolutely leak-proof seams, a testament to MMTECHWELD’s innovation.

Other Global Leaders:

- Lincoln Electric (USA): A global leader renowned for its comprehensive range of arc welding equipment, advanced consumables, and integrated robotic welding systems, serving heavy industrial applications worldwide.

- ESAB (Sweden/USA): Offers a full spectrum of cutting-edge welding and cutting equipment, high-performance consumables, and innovative automation solutions, serving a remarkably diverse range of industries across the globe.

- Miller Electric (USA): Universally celebrated for its exceptionally robust and reliable welding equipment, specializing in a wide array of arc welding solutions and essential accessories that stand up to the toughest jobs.

- Fronius International GmbH (Austria): Recognized for its technological leadership in advanced arc welding and precise resistance spot welding, with a strong strategic focus on pioneering digital solutions and promoting environmental sustainability in manufacturing.

- Jasic Technology (China): A significant and growing player in both the domestic Chinese market and on the global stage, offering highly cost-effective and high-performance inverter welding machines and cutting equipment that appeal to a broad customer base.

Market Outlook & Opportunities: Charting the Future of Fabrication

The trajectory of the welding and cutting industry is unequivocally forward, marked by an acceleration of technological integration and an increasingly sophisticated buyer demand. Upcoming trends underscore a definitive drive towards greater sophistication, enhanced adaptability, and a strong emphasis on operational intelligence.

- The Rise of Smart Manufacturing and Industry 4.0 Integration: Manufacturers are increasingly seeking welding and cutting solutions that can seamlessly integrate into broader smart factory ecosystems. This includes machinery equipped with advanced IoT (Internet of Things) capabilities, enabling real-time data analytics, remote monitoring, and predictive diagnostic features for optimal performance and proactive issue resolution. These smart solutions offer unprecedented levels of control and insight.

- Surging Demand for Automation and Robotics: Persistent labor costs, coupled with a widening skill gap in many regions, are compelling businesses to invest heavily in automated welding and cutting cells. This translates into a high demand for advanced robotic welders, collaborative robots (cobots) that can work alongside human operators, and fully automated Hot cutting pipe machines. These solutions are capable of executing complex tasks with precision, consistency, and minimal human intervention, dramatically improving throughput and reducing operational variances.

- Sustainability and Energy Efficiency as Core Drivers: Green manufacturing is no longer a peripheral concern but a central imperative. Buyers are prioritizing equipment that actively reduces energy consumption, minimizes material waste, and operates with a smaller carbon footprint. This critical demand is fueling intense innovation in inverter technology, energy recovery systems, and the development of eco-friendly consumables for heat fusion machines, reflecting a global commitment to responsible industrial practices.

- Advanced Material Processing Capabilities: The increasing adoption of exotic alloys, high-performance composites, and ultra-high-strength steels in modern construction, automotive, and aerospace manufacturing necessitates welding and cutting solutions capable of handling these challenging materials with absolute precision and impeccable integrity. The market is trending towards machines that offer multi-process capabilities and adaptive control systems to master these diverse material requirements.

Opportunities abound for both manufacturers and discerning buyers in these rapidly evolving domains. Strategic investments in automation can unlock unprecedented productivity gains and address labor challenges, while embracing smart manufacturing solutions offers enhanced control, predictive capabilities, and superior quality assurance. Focusing on sustainable practices not only fulfills increasingly stringent regulatory requirements but also resonates powerfully with a growing market demand for environmentally responsible industrial operations, creating a significant competitive advantage.

Buyer & Business Takeaways: Strategic Investments for the Future

For B2B decision-makers, understanding these profound shifts in the welding and cutting industry is paramount for making informed procurement and partnership decisions. Investing in advanced heat fusion machine and Hot cutting pipe machine technologies today is not merely an incremental upgrade; it represents a strategic imperative for ensuring long-term competitiveness, resilience, and growth in a dynamic global market.

-

Why Investing in Modern Welding & Cutting Equipment Makes Sense:

- Enhanced Productivity and Throughput: Automated systems and faster, more precise machines significantly increase production output, often operating continuously with minimal supervision.

- Superior Quality and Consistency: Advanced controls, digital feedback loops, and robotic precision lead to consistently higher-quality welds and cuts, drastically reducing rework and material scrap.

- Significant Cost Efficiency: Modern equipment contributes to substantial savings through reduced material waste, lower energy consumption (especially with inverter technology), minimized labor costs, and extended equipment lifespan via predictive maintenance.

- Improved Workplace Safety: Automation minimizes human exposure to hazardous environments (fumes, intense light, high temperatures), thereby enhancing worker safety and reducing the risk of industrial accidents.

-

Tips for Adopting or Partnering with Chinese Manufacturers:

- Conduct Thorough Due Diligence: Rigorously research manufacturer reputation, international certifications (e.g., CE, ISO), and track record. Look for companies like MMTECHWELD that demonstrate transparent manufacturing processes, adhere to strict quality control, and show a clear commitment to international standards.

- Prioritize Robust After-Sales Support: Ensure that potential partners offer strong warranties, guarantee readily available spare parts, and provide responsive, competent technical assistance. This minimizes downtime and protects your investment.

- Focus on Total Cost of Ownership (TCO): Beyond the initial purchase price, carefully evaluate the complete economic impact. Consider factors like energy efficiency, routine maintenance costs, and the expected operational lifespan of equipment, particularly for critical assets like the CX600 Hot Wedge Machine.

- Evaluate Customization & Scalability Options: Partner with manufacturers who can offer solutions tailored precisely to your specific operational needs and who have the capability to scale their offerings as your business evolves and grows.

-

Future-Proof Strategies for Sustainable Growth:

- Embrace Comprehensive Digitalization: Invest strategically in equipment with smart features, IoT connectivity, and data integration capabilities to build a truly connected, intelligent, and responsive factory environment.

- Invest in Workforce Training and Development: Ensure your workforce is adequately trained and continuously upskilled to proficiently operate, program, and maintain advanced machinery, maximizing your technological investments.

- Prioritize Flexibility & Adaptability: Choose modular and scalable solutions that can be easily reconfigured or expanded. This ensures your operations can swiftly adapt to changing production demands, evolving material advancements, and new market opportunities.

Conclusion: Seizing the Future at Beijing Essen

The Beijing Essen Welding & Cutting Fair serves as a vital barometer and an indispensable compass for the global heat fusion machine and Hot cutting pipe machine markets. It is not just an event; it’s a dynamic ecosystem where innovation is celebrated, strategic partnerships are forged, and the future trajectory of fabrication technology is actively shaped. For B2B stakeholders, the invaluable insights gained, the cutting-edge technologies showcased, and the critical connections made at this prestigious event are absolutely essential for staying ahead in an increasingly competitive and rapidly evolving industrial landscape.

As the industry continues its accelerating shift towards greater automation, enhanced intelligence, and pervasive sustainability, manufacturers like HEBEI MINGMAI TECHNOLOGY CO., LTD. are positioned at the forefront of this transformation. They are consistently delivering advanced, high-performance solutions that not only meet but often exceed the stringent demands of modern production environments. Their unwavering commitment to superior quality, continuous technological advancement, and a highly competitive cost structure firmly establishes them as a strategic and reliable partner for businesses worldwide seeking to optimize their fabrication processes.

Ready to elevate your production capabilities with cutting-edge technology and secure your competitive edge?

Explore MMTECHWELD’s advanced solutions, including the robust and reliable CX600 Hot Wedge Machine.

Discover the CX600 Hot Wedge Machine and Its Benefits

MM-Tech, established in 2011, is a leading manufacturer of thermoplastic welding equipment in China.hot air plastic welder We specialize in the research, development, production, and sales of thermoplastic welding equipment.hot air welding gun Our product line is extremely rich, covering geomembrane welders, polymer hot air welders, tarpaulin hot air welders, hot air welders, hand extrusion welders, and various welding tools, comprehensively meeting the diverse needs of both on-site construction and workshop operations.hot air welder roofing Our products have been exported to over 100 countries and have won the trust of more than 3,000 customers.plastic welding heat gun|super blog