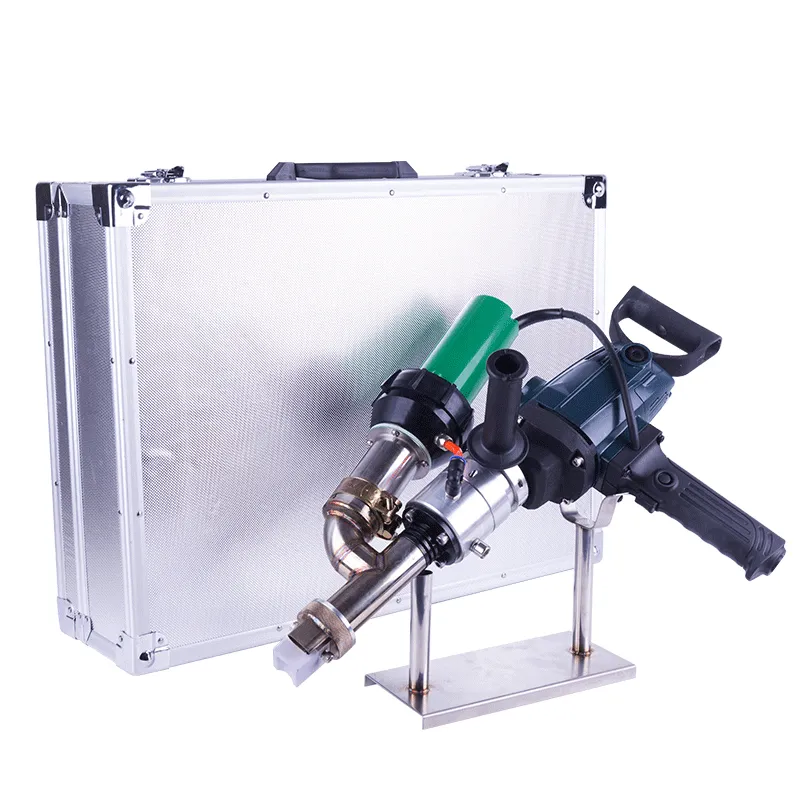

SWT-NS600F: A hands-on look at modern extrusion welding

If you’ve been shopping for a plastic extrusion welding machine, you’ve probably noticed the category moving fast—bigger output, safer controls, smarter nozzles. I’ve spent enough time on job sites to know the difference between spec-sheet promise and field reality. The SWT-NS600F hand extruder from MM-Tech (origin: NO.355, Youyi Street, Qiaoxi District, Shijiazhuang, Hebei, China) lands in that “gets it done” zone: designed for PP, PE, PVDF, and other hot-melt thermoplastics, with a notably generous extrusion volume.

Where it fits in the market

Industry trend, short version: more thermoplastic tanks, geomembranes, and thick-wall PE pipe repairs happening on site, not just in the shop. Contractors want fewer passes and cleaner seams. The SWT-NS600F leans into that with high throughput and interchangeable shoes for pipes and membrane structures. Many customers say it feels “less fussy” than older guns—partly thanks to stable barrel heating and straightforward controls. To be honest, that’s what crews actually need at 6 a.m. on a windy landfill.

Core specs (real-world, not just catalog)

| Model | SWT-NS600F |

| Compatible materials | PP, PE, PVDF (and similar hot-melt thermoplastics) |

| Extrusion output | ≈ 2.5–6.0 kg/h (real-world use may vary with rod, shoe, ambient) |

| Welding rod | Typically 3–4 mm, round; material matched to base sheet/pipe |

| Heating | Separate air preheat and barrel heating for stable melt profile |

| Welding shoes | Changeable shoes for membranes, fillets, and pipe repair |

| Typical applications | Geomembranes, chemical tanks, PE pipe repair, ducting, liners |

Process flow (how teams actually run it)

- Materials: PP/PE/PVDF base; matching welding rod (no mixing, please).

- Prep: Edge bevel and clean with lint-free wipes; remove oxidation on PE.

- Method: Hot-air preheat of parent material + controlled barrel melt; steady travel; avoid overbead bulking.

- Parameters: Shoe temp set per DVS 2207 guidance; keep interpass temp consistent; ambient wind shielding helps.

- Inspection & testing: Visual per DVS 2202; seam testing per DVS 2203 and ASTM D6392 for geomembranes; tensile per ASTM D638 (samples).

- Service life: Around 10–25 years for joints in civil/industrial environments, depending on UV, chemicals, stress cycles, and correct WPS adherence.

In membrane work, a plastic extrusion welding machine is often paired with vacuum box testing and peel/shear coupons. On pipes, I still recommend bead removal and sample pulls when feasible—cheap insurance.

Vendor snapshot (what buyers actually compare)

| Vendor | SWT-NS600F (MM-Tech) | Generic Import | EU Premium Brand |

|---|---|---|---|

| Certifications | CE; aligns with DVS process guidance | CE (varies) | CE; sometimes UL/CSA regionally |

| Extrusion output | High (≈ 2.5–6.0 kg/h) | Medium (≈ 2–4 kg/h) | High (≈ 3–6 kg/h) |

| Warranty & service | Structured support; parts availability | Varies by reseller | Strong but pricier |

| Lead time | Around 2–4 weeks | Uncertain | 4–8 weeks |

Use cases, feedback, and a quick case file

- Industries: Waste containment (HDPE liners), chemical tank fabrication, ventilation ducting, aquaculture, municipal PE pipe repair.

- Customer note: “Output-to-weight ratio is solid; holds temp in crosswind better than our old unit.”

- Case file: Geomembrane repair, 1.5 mm HDPE; travel ≈ 0.8–1.2 m/min; passed ASTM D6392 peel/shear with safety margin >15% over spec.

If your crew rotates operators, the learning curve matters. A plastic extrusion welding machine with consistent melt and intuitive controls saves rework—quietly, over months—that’s the real ROI.

Customization and QA

Common custom options include shoe geometry, cordsets/voltages, and rod guides matched to PP/PE/PVDF. For QA, I like a simple WPS/WPQR bundle referencing DVS 2207 for parameters, plus EN 13067 for welder qualification. Throw in routine coupon tests per DVS 2203—nothing fancy, just disciplined.

Standards you’ll see on submittals

- DVS 2207 (extrusion welding guidance for thermoplastics)

- DVS 2203 (testing of welded joints in thermoplastics)

- ASTM D6392 (geomembrane seam strength), ASTM D4437 (field QC)

- EN 13067 (qualification of thermoplastic welders)

- ISO 21307 / ISO 12176 (PE piping procedures and systems)

Citations

- DVS 2207-4: Welding of thermoplastics – Extrusion welding (German Welding Society).

- DVS 2203: Testing of welded joints between thermoplastics (German Welding Society).

- ASTM D6392: Standard Test Method for Determining the Integrity of Nonreinforced Geomembrane Seams.

- ASTM D4437: Practice for Field Seam Quality Control of Thermoplastic Geomembranes.

- EN 13067: Plastics welding — Qualification of welders.

- ISO 21307 / ISO 12176 series: Plastics piping systems for PE — fusion/jointing procedures and equipment.

MM-Tech, established in 2011, is a leading manufacturer of thermoplastic welding equipment in China.hot air plastic welder We specialize in the research, development, production, and sales of thermoplastic welding equipment.hot air welding gun Our product line is extremely rich, covering geomembrane welders, polymer hot air welders, tarpaulin hot air welders, hot air welders, hand extrusion welders, and various welding tools, comprehensively meeting the diverse needs of both on-site construction and workshop operations.hot air welder roofing Our products have been exported to over 100 countries and have won the trust of more than 3,000 customers.plastic welding heat gun|super blog