The SWT-NSGM1 Geomembrane Welding Machine is a cutting-edge solution designed to meet the demands of modern geo-synthetic engineering. This innovative device is engineered to weld a wide range of geomembranes, offering precision, durability, and adaptability across various industries. With its advanced features and robust technical specifications, the SWT-NSGM1 is a reliable tool for professionals in fields such as landfill management, aquaculture, and infrastructure development. This article explores the product’s key features, applications, and technical details, along with insights into the company behind this technology.

Product Video

Applications of the SWT-NSGM1 Geomembrane Welding Machine

The SWT-NSGM1 is a versatile tool that excels in multiple industries. Its primary applications include:

- Landfills: Ensuring impermeability to prevent environmental contamination.

- Biogas Digesters: Providing a secure seal for waste-to-energy systems.

- Mining Treatment: Protecting against chemical leaks and soil contamination.

- Highway and Railway Tunnels: Offering waterproofing solutions for underground structures.

- Aquaculture: Creating durable ponds for fish and shrimp farming.

- Reservoir Dams: Ensuring long-term water retention and structural integrity.

- Agricultural Irrigation: Preventing water loss in irrigation systems.

The machine’s ability to handle diverse materials and environments makes it an indispensable asset for professionals in the geo-synthetic industry. For more details on its applications, visit the SWT-NSGM1 product page.

Product Specifications Table

| Input Voltage | 230V/120V |

| Frequency | 50/60HZ |

| Power | 1400W |

| Overlap Width | 12 cm |

| Welding Speed | 0.5-6 m/min |

| Temperature | 50-450℃ |

| Seam Strength | ≥85% Original |

| Seam Width | 15 mm2, Interior Cavity 15 mm |

| Welding Material Thickness | 0.2-2 mm |

| Feeding Method | From two sides |

| Digital Display | Temperature & Speed |

| Gross/Net Weight | 15.0 Kg/9.0 Kg |

| Packing Size | 340 mm (L) × 350 mm (W) × 360 mm (H) |

Key Features of the SWT-NSGM1

The SWT-NSGM1 is equipped with advanced features that enhance its performance and usability:

- Digital Control System: The machine features a high-precision digital display for accurate temperature and speed control, ensuring consistent welding results.

- Advanced Motor System: The innovative jib design and pressure regulation structure optimize welding efficiency and reduce operational strain.

- Stainless Steel Pressure Roller: Designed for durability, the pressure roller provides strong, non-slip contact, ensuring even pressure distribution during welding.

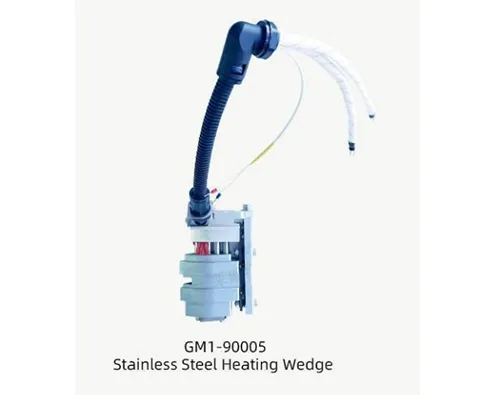

- Customized Heating System: The metal hot wedge with high-efficiency heating elements ensures rapid and uniform heating, extending the machine’s lifespan.

These features collectively contribute to the SWT-NSGM1’s reliability and efficiency, making it a preferred choice for professionals in the geo-synthetic industry.

Weldable Materials

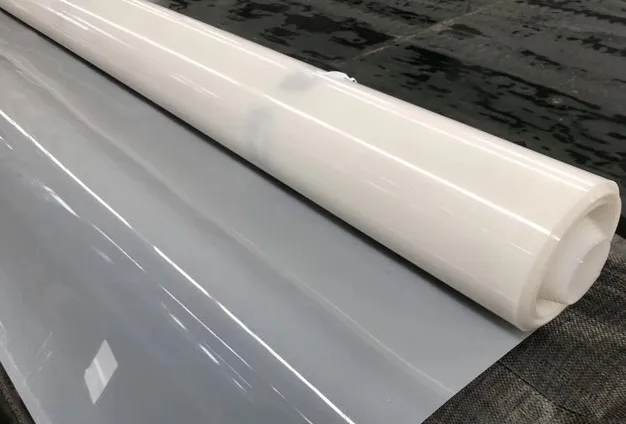

The SWT-NSGM1 is compatible with a wide range of materials, including:

- PE (Polyethylene): Ideal for applications requiring flexibility and chemical resistance.

- PP (Polypropylene): Known for its durability and thermal stability.

- PVC (Polyvinyl Chloride): Offers excellent resistance to weathering and UV exposure.

- EVA (Ethylene-Vinyl Acetate): Provides superior flexibility and adhesion properties.

For a visual demonstration of these materials, refer to the images below:

Product Images

Company Background: Hebei Mingmai Technology Co., Ltd.

Hebei Mingmai Technology Co., Ltd. is a leading manufacturer of welding equipment, specializing in innovative solutions for the geo-synthetic industry. With a focus on quality and technological advancement, the company has established itself as a trusted name in the field. Their commitment to research and development ensures that their products, such as the SWT-NSGM1, meet the highest industry standards. For more information about the company, visit their official website.

Technical Advantages and Performance

The SWT-NSGM1’s technical specifications highlight its superiority in performance and versatility:

- High Power Output: The 1400W motor ensures efficient operation even under demanding conditions.

- Wide Temperature Range: Operating between 50-450℃ allows the machine to handle various materials with precision.

- Adjustable Welding Speed: The 0.5-6 m/min range accommodates different project requirements, enhancing productivity.

- Durable Construction: The stainless steel pressure roller and robust housing ensure long-term reliability.

These technical advantages make the SWT-NSGM1 a versatile and durable choice for professionals seeking high-performance welding solutions.

Why Choose the SWT-NSGM1?

The SWT-NSGM1 stands out in the market due to its combination of advanced technology and user-friendly design. Key reasons to choose this machine include:

- Precision and Consistency: The digital control system ensures accurate welding, reducing material waste and rework.

- Versatility: Compatible with multiple materials and thicknesses, the machine adapts to various project needs.

- Ease of Use: Intuitive controls and a compact design make it accessible for both novice and experienced operators.

- Cost-Effectiveness: The machine’s efficiency and durability contribute to long-term savings for businesses.

For a detailed comparison with other welding machines, visit the SWT-NSGM1 product page.

Authoritative References and Industry Standards

The development and application of welding technologies like the SWT-NSGM1 are guided by industry standards and research. The National Institute of Standards and Technology (NIST) plays a critical role in establishing measurement standards that ensure the quality and reliability of such equipment. According to NIST, “Standards and measurements are essential for innovation and the advancement of technology in various sectors” (NIST.gov). The SWT-NSGM1 aligns with these principles, offering precise and consistent performance that meets industry benchmarks.

Conclusion

The SWT-NSGM1 Geomembrane Welding Machine is a testament to innovation in the geo-synthetic industry. Its advanced features, technical specifications, and versatility make it an ideal choice for a wide range of applications. By combining precision, durability, and user-friendly design, the SWT-NSGM1 sets a new standard for welding equipment. For more information or to purchase the machine, visit the SWT-NSGM1 product page today.

References

National Institute of Standards and Technology (NIST). (n.d.). What We Do. Retrieved from https://www.nist.gov/

MM-Tech, established in 2011, is a leading manufacturer of thermoplastic welding equipment in China.hot air plastic welder We specialize in the research, development, production, and sales of thermoplastic welding equipment.hot air welding gun Our product line is extremely rich, covering geomembrane welders, polymer hot air welders, tarpaulin hot air welders, hot air welders, hand extrusion welders, and various welding tools, comprehensively meeting the diverse needs of both on-site construction and workshop operations.hot air welder roofing Our products have been exported to over 100 countries and have won the trust of more than 3,000 customers.plastic welding heat gun|super blog