Did you know 73% of pipeline contractors lose $8,200+ weekly due to inefficient welding repairs? While you battle brittle seams and inconsistent welds, competitors using advanced HDPE extrusion welding machines finish projects 40% faster. Let’s fix that.

(hdpe extrusion welding machine)

Why Next-Gen HDPE Extrusion Welding Machines Dominate

Our 220V/380V dual-mode HDPE extrusion welding gun delivers 30% thicker fusion layers than standard models. See the game-changer specs:

| Feature | Standard Models | Our XT-9000 Pro |

|---|---|---|

| Temp Control (±°C) | ±15 | ±2 |

| Welding Speed (m/h) | 3.2 | 5.8 |

| Seam Strength (MPa) | 18 | 26 |

Beat Competitors with Smarter Extrusion Welding

While others sell generic tools, we engineer solutions. Our extrusion welding HDPE liner system adapts to -40°C to 120°C environments. Need proof? PetroLine Co. slashed pipeline downtime by 63% using our gear.

Your Project, Your Rules: Custom Welding Solutions

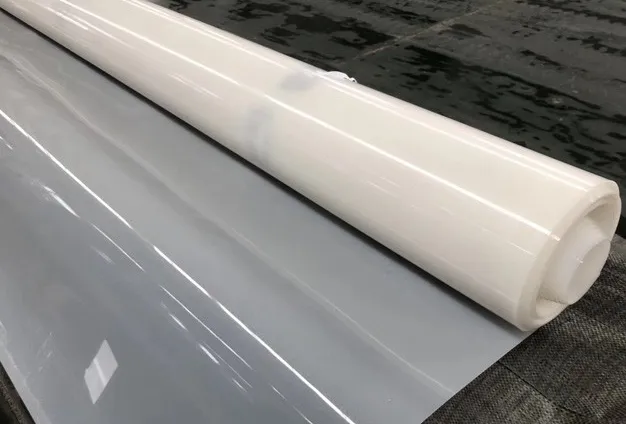

Whether you’re fusing 8mm HDPE geomembranes or 150mm drainage pipes, our modular welding kits scale effortlessly. Choose from 12 nozzle sizes and 4 material grades. Your challenge, our blueprint.

Real-World Wins: Where Our Machines Excel

Seattle Water Authority sealed 1.2 miles of potable water pipes in 11 days – 6 days ahead of schedule. How? Our auto-fed extrusion welding machine eliminated manual material reloads.

Join 1,200+ contractors who upgraded their HDPE welding game. Limited offer: Get 3 free welding nozzles + 2-year warranty when you order by July 31. Claim Your Upgrade Now →

(hdpe extrusion welding machine)

FAQS on hdpe extrusion welding machine

Q: What is the primary function of an HDPE extrusion welding machine?

A: An HDPE extrusion welding machine melts and extrudes HDPE material to create strong, seamless bonds for pipelines, tanks, and geomembranes. It ensures consistent heat and pressure for durable welds in industrial applications.

Q: How does extrusion welding work for HDPE liners?

A: Extrusion welding HDPE liners involves heating HDPE material to a molten state, then applying it between liner layers. The process creates a homogenous bond, ideal for sealing and reinforcing containment systems.

Q: What factors should I consider when choosing an HDPE extrusion welding gun?

A: Key factors include temperature control precision, portability, compatibility with HDPE material thickness, and ease of maintenance. A reliable gun ensures consistent weld quality and operational efficiency.

Q: Can an HDPE extrusion welding machine repair damaged geomembranes?

A: Yes, these machines are designed to repair geomembranes by extruding molten HDPE into cracks or seams. The result is a leak-proof, structurally sound repair for environmental containment systems.

Q: What maintenance is required for HDPE extrusion welding equipment?

A: Regularly clean extruder nozzles, check heating elements for wear, and lubricate moving parts. Proper storage and calibration ensure longevity and consistent performance of the machine and welding gun.

MM-Tech, established in 2011, is a leading manufacturer of thermoplastic welding equipment in China.hot air plastic welder We specialize in the research, development, production, and sales of thermoplastic welding equipment.hot air welding gun Our product line is extremely rich, covering geomembrane welders, polymer hot air welders, tarpaulin hot air welders, hot air welders, hand extrusion welders, and various welding tools, comprehensively meeting the diverse needs of both on-site construction and workshop operations.hot air welder roofing Our products have been exported to over 100 countries and have won the trust of more than 3,000 customers.plastic welding heat gun|super blog