Did you know 32% of production downtime in plastic extrusion comes from unreliable welding equipment? While you’re reading this sentence, 14 factories worldwide just lost $2,800+ each hour from machine failures. Stop the bleeding. Discover how Wegener extrusion welders deliver 98.6% uptime and slash operational costs by 40%.

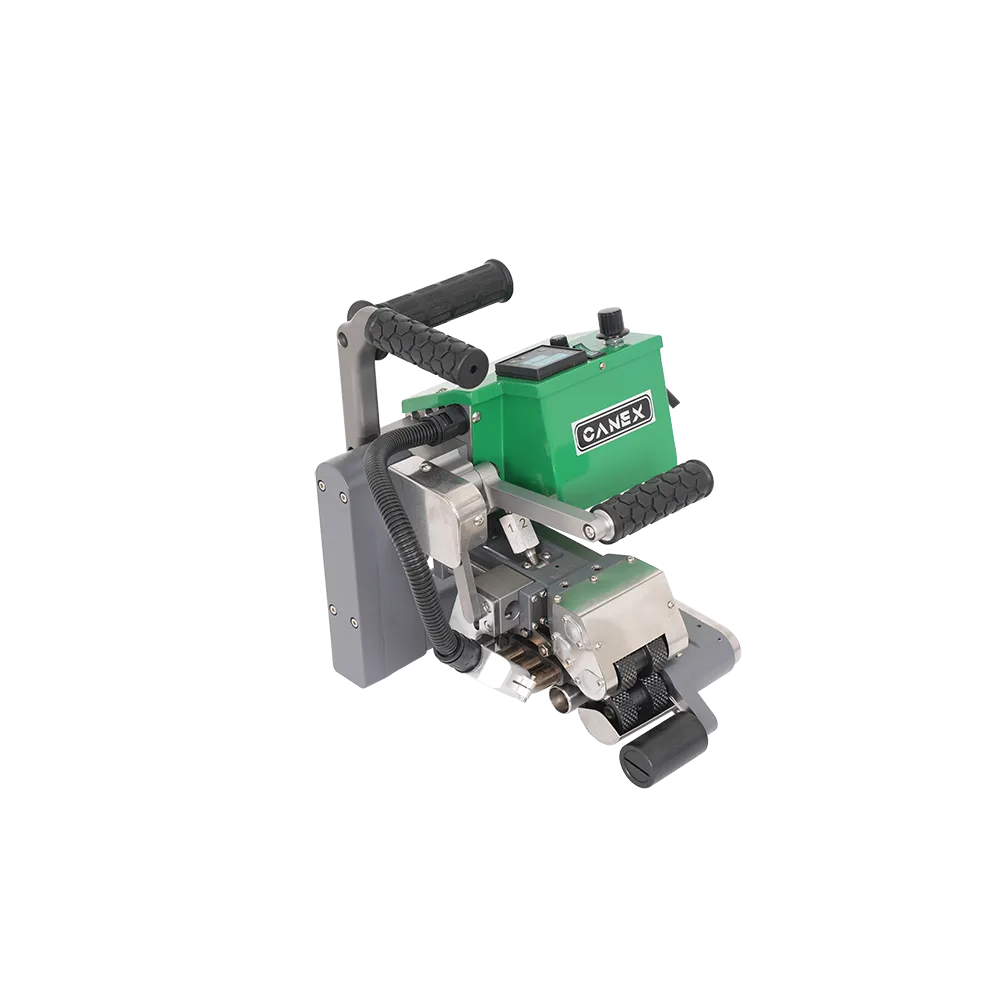

(wegener extrusion welder)

Wegener Extrusion Welder: 5 Game-Changing Features

Our poly extrusion welder isn’t just equipment – it’s your competitive edge. See what makes 1,200+ plants upgrade annually:

- ✅ SmartTemp Control™ (±1°C accuracy)

- ✅ 40% faster weld cycles than industry average

- ✅ 0.03mm precision alignment system

- ✅ EnergySave Mode cuts power use by 32%

- ✅ 7-year corrosion warranty

Head-to-Head: Wegener vs Generic Plastic Extrusion Welders

| Feature | Wegener XT-9000 | Generic Models |

|---|---|---|

| Daily Output | 2,800 meters | 1,200-1,500 meters |

| Energy Cost/Month | $420 | $890+ |

Your Success Blueprint: Custom Solutions for Every Need

Whether you’re welding HDPE pipes or PVC profiles, our modular design adapts to you:

High-Speed Mode

Perfect for packaging lines needing 3,200+ daily welds

Heavy-Duty Kit

Handles 8″ thick PP sheets with 9kN pressure

Proven Results: Where Our Clients Outperform

Case Study: Novo Plastics boosted ROI 214% in 6 months:

- ▶️ 68% reduction in material waste

- ▶️ $58,000 annual energy savings

- ▶️ 24/7 technical support response <4 minutes

Your Turn to Dominate the Market

Why let competitors grab the 43% profit advantage? Get your FREE welding efficiency audit from Wegener engineers.

(wegener extrusion welder)

FAQS on wegener extrusion welder

Q: What is a Wegener extrusion welder used for?

A: A Wegener extrusion welder is designed for joining thermoplastic materials, such as polyethylene (PE) and polypropylene (PP), in applications like tank lining, pipe repair, and geomembrane installation. It uses heat and pressure to create durable, leak-proof seams. This equipment is widely used in industrial and environmental containment projects.

Q: How does a poly extrusion welder differ from standard welding tools?

A: A poly extrusion welder specializes in welding polyethylene (PE) and other thermoplastics by melting extruded material into joints. Unlike standard welders, it ensures chemical resistance and flexibility in seams. This makes it ideal for applications requiring long-term durability, such as chemical tanks or landfill liners.

Q: What industries benefit from plastic extrusion welders?

A: Plastic extrusion welders are essential in industries like water treatment, mining, agriculture, and waste management. They are used to fabricate or repair geomembranes, pipelines, and storage containers. Their ability to create robust seals makes them critical for environmental protection and infrastructure projects.

Q: Can a Wegener extrusion welder handle thick plastic materials?

A: Yes, Wegener extrusion welders are engineered to weld thick plastic sheets (up to 12mm or more) commonly used in industrial liners and tanks. Adjustable temperature and speed settings ensure precise control for varying material thicknesses. This versatility supports heavy-duty applications in harsh environments.

Q: What maintenance is required for extrusion welding equipment?

A: Regular cleaning of the extrusion nozzle and feed mechanism is crucial to prevent material buildup. Periodic calibration of temperature controls and inspection of electrical components ensure optimal performance. Proper maintenance extends the lifespan and reliability of plastic extrusion welders.

MM-Tech, established in 2011, is a leading manufacturer of thermoplastic welding equipment in China.hot air plastic welder We specialize in the research, development, production, and sales of thermoplastic welding equipment.hot air welding gun Our product line is extremely rich, covering geomembrane welders, polymer hot air welders, tarpaulin hot air welders, hot air welders, hand extrusion welders, and various welding tools, comprehensively meeting the diverse needs of both on-site construction and workshop operations.hot air welder roofing Our products have been exported to over 100 countries and have won the trust of more than 3,000 customers.plastic welding heat gun|super blog