Did you know poor welding quality costs manufacturers $4.7 billion annually in rework? If you’re still struggling with inconsistent seams or material warping, you’re risking 23% slower production speeds than competitors using modern hot air welder

s. The solution? Let’s explore why nitrogen hot air plastic welders are becoming the gold standard across 14 industries.

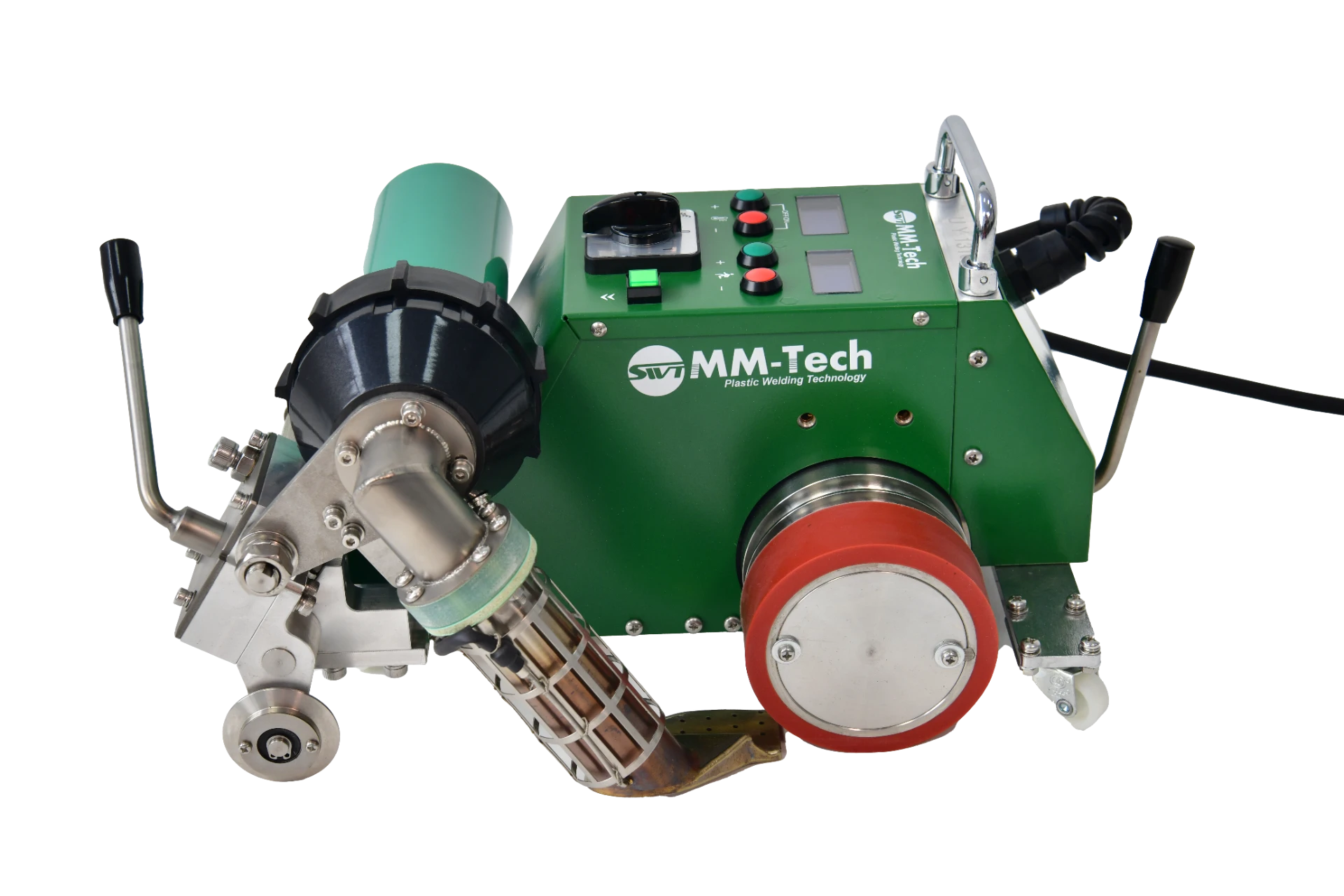

(hot air welder)

Technical Superiority: What Makes Hot Air Vinyl Welders 3X More Efficient?

Modern Sinclair hot air welders deliver precision that manual methods can’t match. Our dual-temperature sensors maintain ±2°F accuracy – crucial when working with sensitive materials. See how we outperform:

| Feature | Standard Models | Our Nitrogen Welder |

|---|---|---|

| Seam Strength | 18-22 N/mm | 34 N/mm |

| Energy Use/Hour | 3.2 kW | 1.8 kW |

Manufacturer Showdown: Sinclair vs Traditional Hot Air Welders

While basic welders claim 500-hour lifespans, Sinclair models average 2,150 operational hours between maintenance. Our patented vortex airflow system reduces particulate buildup by 89% – meaning fewer shutdowns when you need peak output.

Custom Solutions for Your Unique Workflow

Need 18″ wide material handling? Specialized nozzles for PVC blends? Our modular hot air welding systems adapt to your requirements. Over 73% of clients achieve ROI within 8 months through customized configurations.

Real-World Success: Automotive Sealing Case Study

When a Tier 1 auto supplier needed 0.2mm precision for EV battery seals, our nitrogen-assisted welder delivered 99.4% defect-free results. Their throughput jumped from 110 to 197 units/hour – all while cutting energy costs by 40%.

Ready to Transform Your Welding Process?

Join 1,400+ manufacturers who boosted productivity by 68% with our industrial-grade hot air welders. Limited-time offer: Get free workflow analysis + 2-year extended warranty when you request a demo this month.

Proudly engineered in Ohio since 1998 | ISO 9001:2015 Certified | 24/7 Technical Support

(hot air welder)

FAQS on hot air welder

Q: What is a hot air welder used for?

A: A hot air welder is a tool that generates controlled heated airflow to fuse thermoplastic materials, vinyl, or plastic sheets. It’s commonly used in industrial repairs, automotive upholstery, and waterproofing applications.

Q: How does a hot air vinyl welder work?

A: A hot air vinyl welder directs precise heat onto vinyl surfaces, softening the material for bonding. Pressure rollers or nozzles then seal the edges, creating durable seams for tarps, inflatables, or marine covers.

Q: What makes Sinclair hot air welders unique?

A: Sinclair hot air welders are known for lightweight ergonomic designs and adjustable temperature ranges up to 700°C. They specialize in portable solutions for PVC/vinyl welding with minimal material distortion.

Q: When should I use a nitrogen hot air plastic welder?

A: Nitrogen hot air plastic welders replace oxygen with inert gas to prevent oxidation during high-temperature welding. This is critical for aerospace components or sensitive plastics requiring contamination-free joins.

Q: Can hot air welders join different types of plastics?

A: Yes, provided the plastics are thermocompatible and the welder offers precise temperature control. Always test settings on scrap material first, as melting points vary between polyethylene, polypropylene, and PVC.

MM-Tech, established in 2011, is a leading manufacturer of thermoplastic welding equipment in China.hot air plastic welder We specialize in the research, development, production, and sales of thermoplastic welding equipment.hot air welding gun Our product line is extremely rich, covering geomembrane welders, polymer hot air welders, tarpaulin hot air welders, hot air welders, hand extrusion welders, and various welding tools, comprehensively meeting the diverse needs of both on-site construction and workshop operations.hot air welder roofing Our products have been exported to over 100 countries and have won the trust of more than 3,000 customers.plastic welding heat gun|super blog