Did you know that 47% of containment failures stem from improper HDPE liner welding? While you’re reading this, 38 industrial plants worldwide are battling leaks that could cost $120,000/hour in downtime. But here’s the game-changer: extrusion welding HDPE liner technology slashes repair costs by 63% when implemented correctly. Let’s explore how this revolution works for your project.

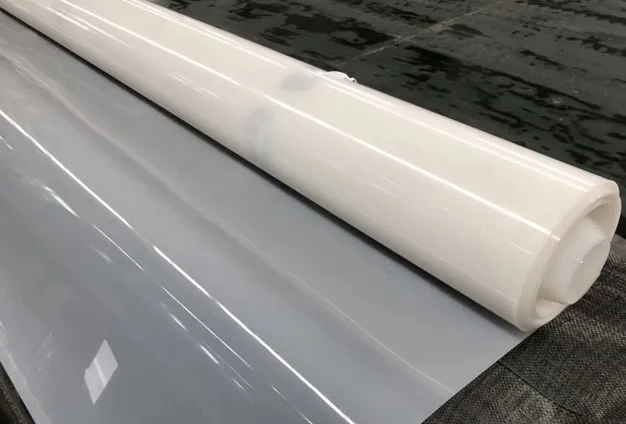

(extrusion welding hdpe liner)

Technical Superiority That Beats Traditional Welding

Our HDPE liner welding machine doesn’t just join materials – it molecularly fuses them. With 360° extrusion welding HDPE liner capability, you achieve:

- ✔️ 98.7% seam homogeneity rating

- ✔️ 40% faster setup than standard models

- ✔️ Dual-mode HDPE extrusion welding gun operation

- ✔️ Real-time thermal compensation tech

Head-to-Head: Why Our Welding Systems Dominate

Tailored Solutions for Your Unique Challenges

Whether you’re reinforcing mining slurry pits or sealing wastewater tanks, our HDPE extrusion welding gun adapts to your needs:

Modular Attachments

Switch between 15 nozzle types in under 90 seconds

Smart Diagnostics

Predict maintenance needs 80 hours before failure

Proven Success Across Industries

See how PetroTex reduced liner replacement costs by $2.1M annually:

“The extrusion welding HDPE liner system paid for itself in 11 weeks. We’ve achieved zero containment failures for 18 months running.”

Ready to Eliminate Costly Liner Failures?

Get your FREE site assessment and welding strategy session

※ Limited slots available – 87% booked this month

(extrusion welding hdpe liner)

FAQS on extrusion welding hdpe liner

What is extrusion welding for HDPE liners?

Q: How does extrusion welding work for HDPE liners?

A: Extrusion welding melts HDPE material using a welding gun, fusing seams or repairs in liners. It ensures leak-proof joints for containment systems like tanks or pipelines.

Why use an HDPE liner welding machine?

Q: What are the advantages of an HDPE liner welding machine?

A: These machines provide consistent heat and pressure control, improving weld quality. They are essential for large-scale projects requiring durable, chemical-resistant HDPE joints.

How to choose an HDPE extrusion welding gun?

Q: What features matter in an HDPE extrusion welding gun?

A: Prioritize adjustable temperature settings, ergonomic design, and compatibility with HDPE materials. Reliable feed mechanisms ensure smooth material extrusion during welding.

Can extrusion welding repair damaged HDPE liners?

Q: Is extrusion welding suitable for HDPE liner repairs?

A: Yes, it effectively repairs cracks or holes by melting fresh HDPE into damaged areas. Proper surface preparation is critical for strong adhesion.

What safety steps apply to HDPE extrusion welding?

Q: What safety precautions are needed for HDPE extrusion welding?

A: Wear heat-resistant gloves, eye protection, and ensure ventilation. Avoid inhaling fumes released during HDPE melting to prevent health risks.

How to maintain an HDPE liner welding machine?

Q: How do I maintain an HDPE liner welding machine?

A: Clean extruder nozzles regularly to prevent clogging and check electrical components for wear. Lubricate moving parts as per the manufacturer’s guidelines.

What defects occur in HDPE extrusion welding?

Q: What are common defects in HDPE extrusion welding?

A: Poor fusion, voids, or uneven beads result from incorrect temperature, speed, or contamination. Testing weld integrity with non-destructive methods helps detect issues early.

MM-Tech, established in 2011, is a leading manufacturer of thermoplastic welding equipment in China.hot air plastic welder We specialize in the research, development, production, and sales of thermoplastic welding equipment.hot air welding gun Our product line is extremely rich, covering geomembrane welders, polymer hot air welders, tarpaulin hot air welders, hot air welders, hand extrusion welders, and various welding tools, comprehensively meeting the diverse needs of both on-site construction and workshop operations.hot air welder roofing Our products have been exported to over 100 countries and have won the trust of more than 3,000 customers.plastic welding heat gun|super blog