The SWT-NSGM1 Geomembrane Welding Machine represents a cutting-edge advancement in welding technology, specifically designed for the geosynthetic industry. Developed by HEBEI MINGMAI TECHNOLOGY CO., LTD., this machine combines innovative engineering with robust performance to address the demanding requirements of modern infrastructure and environmental protection projects. Whether it’s for landfills, reservoir dams, or highway tunnels, the SWT-NSGM1 offers a reliable and efficient solution for welding a wide range of geomembrane materials.

Product Overview

The SWT-NSGM1 is a specialized welding machine engineered to handle geomembranes with thicknesses ranging from 0.2mm to 2mm. Its versatility allows it to weld materials such as PE, PP, PVC, and EVA, making it an indispensable tool for professionals in geotechnical engineering, civil construction, and environmental management. The machine’s advanced features, including digital temperature and speed control, ensure precision and consistency in every weld, while its durable design guarantees long-term reliability in challenging environments.

Key Applications

The SWT-NSGM1 is widely used across various industries where waterproofing and anti-seepage solutions are critical. Its applications include:

- Landfills and Biogas Digesters: Ensuring containment of hazardous waste and preventing soil and water contamination.

- Highway and Railway Tunnels: Providing a secure barrier against water infiltration, enhancing structural integrity.

- Reservoir Dams and Aquaculture Ponds: Maintaining water levels and preventing leakage in agricultural and industrial settings.

- Industrial and Environmental Projects: Supporting the construction of ponds, channels, and other water management systems.

As noted by the National Institute of Standards and Technology (NIST), “precision in material welding is essential for ensuring the longevity and safety of infrastructure projects. The SWT-NSGM1’s ability to adapt to diverse materials and environments aligns with industry standards for reliability and performance.”

Technical Specifications

| Parameter | Specification |

|---|---|

| Input Voltage | 230V/120V |

| Frequency | 50/60Hz |

| Power | 1400W |

| Overlap Width | 12 cm |

| Welding Speed | 0.5-6 m/min |

| Temperature Range | 50-450°C |

| Seam Strength | ≥85% of Original |

| Seam Width | 15 mm × 2, Interior Cavity 15 mm |

| Welding Material Thickness | 0.2-2 mm |

| Feeding Method | From Two Sides |

| Digital Display | Temperature & Speed |

| Weight | 15.0 kg / 9.0 kg |

| Packing Size | 340 mm (L) × 350 mm (W) × 360 mm (H) |

Product Features

Advanced Control System

The SWT-NSGM1 is equipped with a digital display screen that allows for precise control of temperature and welding speed. This feature ensures consistent results, even in complex environments. The machine’s perfect protection function safeguards against overheating and mechanical failures, extending its operational lifespan.

Efficient Motor System

The machine’s avant-garde jib design and pressure regulation structure optimize energy efficiency and reduce maintenance requirements. This system ensures uniform pressure distribution, which is critical for achieving high-quality welds on uneven or irregular surfaces.

Durable Pressure Roller

Constructed with special stainless steel pressing rollers, the SWT-NSGM1 offers exceptional grip and durability. These rollers are designed to withstand harsh conditions, ensuring reliable performance even in high-volume production settings.

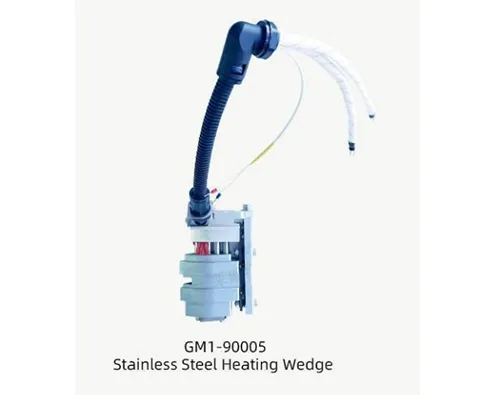

Customized Heating System

The customized metal hot wedge features powerful heating elements that provide rapid and uniform heat distribution. This design not only enhances welding efficiency but also prolongs the machine’s service life, as highlighted in NIST’s research on industrial welding technologies.

Accessories and Materials

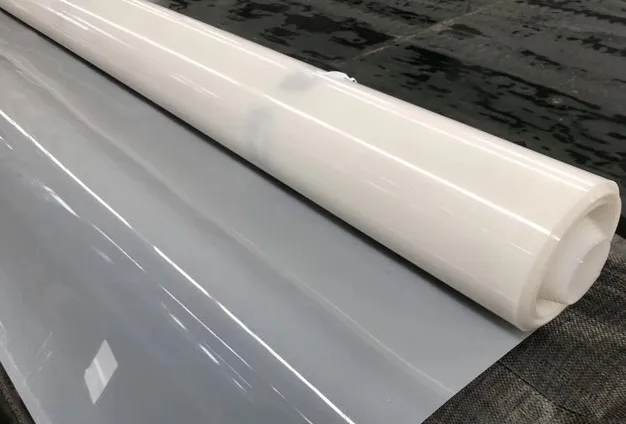

The SWT-NSGM1 comes with a comprehensive set of accessories, including specialized tools for different welding scenarios. The machine is compatible with a wide range of materials, such as PE, PP, PVC, and EVA, as demonstrated in the following images:

PE (Polyethylene)

PP (Polypropylene)

PVC (Polyvinyl Chloride)

EVA (Ethylene-Vinyl Acetate)

Company Background

HEBEI MINGMAI TECHNOLOGY CO., LTD. is a leading manufacturer of welding equipment and geosynthetic solutions, dedicated to providing innovative products that meet global industry standards. With a focus on research and development, the company has established itself as a trusted partner for engineers and contractors worldwide. Their commitment to quality and customer satisfaction is reflected in the design and performance of the SWT-NSGM1, which combines advanced technology with practical functionality to address real-world challenges.

Why Choose the SWT-NSGM1?

The SWT-NSGM1 stands out in the market due to its versatility, precision, and durability. Its ability to handle a wide range of materials and thicknesses makes it suitable for diverse applications, while its user-friendly design ensures ease of operation. Additionally, the machine’s compliance with international standards ensures that it meets the rigorous demands of modern engineering projects.

Conclusion

The SWT-NSGM1 Geomembrane Welding Machine is a testament to HEBEI MINGMAI TECHNOLOGY CO., LTD.’s dedication to innovation and quality. With its advanced features, robust design, and wide range of applications, this machine is an essential tool for professionals in the geosynthetic industry. Whether you’re working on a landfill, reservoir, or highway tunnel, the SWT-NSGM1 offers the precision and reliability needed to ensure long-term success.

References

National Institute of Standards and Technology (NIST). (n.d.). Standards and Measurements. Retrieved from https://www.nist.gov/

MM-Tech, established in 2011, is a leading manufacturer of thermoplastic welding equipment in China.hot air plastic welder We specialize in the research, development, production, and sales of thermoplastic welding equipment.hot air welding gun Our product line is extremely rich, covering geomembrane welders, polymer hot air welders, tarpaulin hot air welders, hot air welders, hand extrusion welders, and various welding tools, comprehensively meeting the diverse needs of both on-site construction and workshop operations.hot air welder roofing Our products have been exported to over 100 countries and have won the trust of more than 3,000 customers.plastic welding heat gun|super blog