Product Overview

The SWT-NSGM1 Geomembrane Welding Machine represents a cutting-edge advancement in welding technology, developed by HEBEI MINGMAI TECHNOLOGY CO., LTD.. This innovative equipment is designed to weld a broad spectrum of geomembranes, capable of handling materials with thicknesses ranging from 0.2mm to 2mm. Its versatility extends to welding various hot-melt materials, including HDPE, LDPE, PP, PVC, and EVA, making it an essential tool for professionals in the geosynthetic industry.

Product Video

Watch the SWT-NSGM1 Geomembrane Welding Machine video to see its operation in action. This visual guide demonstrates the machine’s efficiency and precision in real-world applications.

Key Applications

The SWT-NSGM1 is primarily utilized in geotechnical engineering fields such as landfills, biogas digesters, mining treatment, and anti-seepage treatments for highway and railway tunnels. Its adaptability also extends to aquaculture, reservoir dams, and agricultural irrigation systems. The machine’s ability to work with diverse materials ensures it is an indispensable tool for professionals seeking reliable solutions across a wide array of applications.

Technical Specifications

| Parameter | Specification |

|---|---|

| Input Voltage | 230V/120V |

| Frequency | 50/60HZ |

| Power | 1400W |

| Overlap Width | 12 cm |

| Welding Speed | 0.5-6 m/min |

| Temperature | 50-450℃ |

| Seam Strength | ≥85% Original |

| Seam Width | 15 mm2, Interior Cavity 15 mm |

| Welding Material Thickness | 0.2-2 mm |

| Feeding Method | From two sides |

| Digital Display | Temperature & Speed |

| G./N. Weight | 15.0 Kg/9.0 Kg |

| Packing Size | 340 mm (L) × 350 mm (W) × 360 mm (H) |

Product Features

- Control System: The machine employs an advanced digital display screen for precise control and comprehensive protection functions.

- Motor System: Featuring an avant-garde jib design and pressure regulation structure for enhanced performance.

- Pressure Roller: Equipped with special stainless steel pressing rollers that offer strong pressure, non-slip properties, and durability.

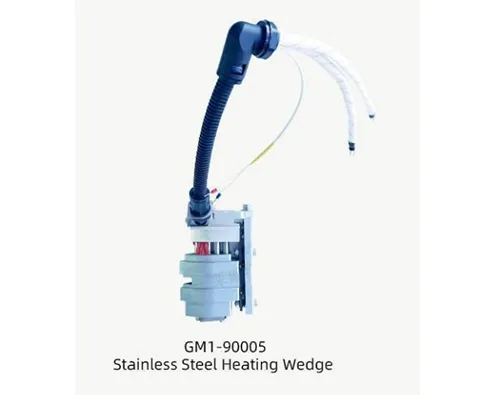

- Heating System: Customized metal hot wedges with powerful heating elements for increased efficiency and longevity.

Accessory List

Weldable Materials

-

PE

-

PP

-

PVC

-

EVA

Company Background

HEBEI MINGMAI TECHNOLOGY CO., LTD. is a leading manufacturer specializing in geosynthetic welding solutions. With a commitment to innovation and quality, the company provides advanced equipment for various industries, ensuring reliable and efficient performance in critical applications. Their expertise in developing cutting-edge technologies like the SWT-NSGM1 Geomembrane Welding Machine underscores their dedication to meeting the evolving needs of the geosynthetic sector.

Industry Relevance and Standards

The SWT-NSGM1 aligns with NIST standards for precision and reliability in engineering applications. As highlighted by the National Institute of Standards and Technology (NIST), “Precision measurements and research are crucial for advancing technology and improving the quality of life for all Americans” (NIST). This machine’s technical specifications and performance capabilities reflect the importance of adhering to such standards in geotechnical engineering.

Conclusion

The SWT-NSGM1 Geomembrane Welding Machine is a testament to the advancements in welding technology, offering a versatile and reliable solution for a wide range of applications. Its robust features, technical excellence, and alignment with industry standards make it an invaluable asset for professionals in the geosynthetic industry. For more information, visit HEBEI MINGMAI TECHNOLOGY CO., LTD..

References

NIST (National Institute of Standards and Technology). “Driving Innovation.” Retrieved from https://www.nist.gov.

MM-Tech, established in 2011, is a leading manufacturer of thermoplastic welding equipment in China.hot air plastic welder We specialize in the research, development, production, and sales of thermoplastic welding equipment.hot air welding gun Our product line is extremely rich, covering geomembrane welders, polymer hot air welders, tarpaulin hot air welders, hot air welders, hand extrusion welders, and various welding tools, comprehensively meeting the diverse needs of both on-site construction and workshop operations.hot air welder roofing Our products have been exported to over 100 countries and have won the trust of more than 3,000 customers.plastic welding heat gun|super blog