The Evolution and Impact of Extrusion Welding Technology

The landscape of industrial plastic fabrication has been significantly transformed by advanced welding techniques, among which extrusion welding stands out for its robust and reliable joint creation. A plastic extrusion welding machine is an indispensable tool in sectors requiring the permanent joining of thermoplastic sheets, pipes, and membranes. This technology ensures hermetic seals and high-strength bonds critical for demanding applications.

Recent industry trends highlight a growing demand for automated and semi-automated extrusion welding solutions that offer enhanced precision, increased welding speed, and superior material compatibility. As environmental regulations tighten and infrastructure projects expand, the need for durable, corrosion-resistant plastic structures, particularly those made from HDPE, PP, and PVC, continues to drive innovation in this field. The focus is increasingly on machines that provide consistent weld quality, reduce operator fatigue, and can handle a wide range of material thicknesses and joint geometries.

This article delves into the intricacies of modern extrusion welding technology, covering everything from manufacturing processes and technical specifications to diverse application scenarios and the critical factors for vendor selection. We aim to provide a comprehensive overview for B2B decision-makers and engineers seeking optimal welding solutions.

Manufacturing Process of a Modern Extrusion Welding Machine

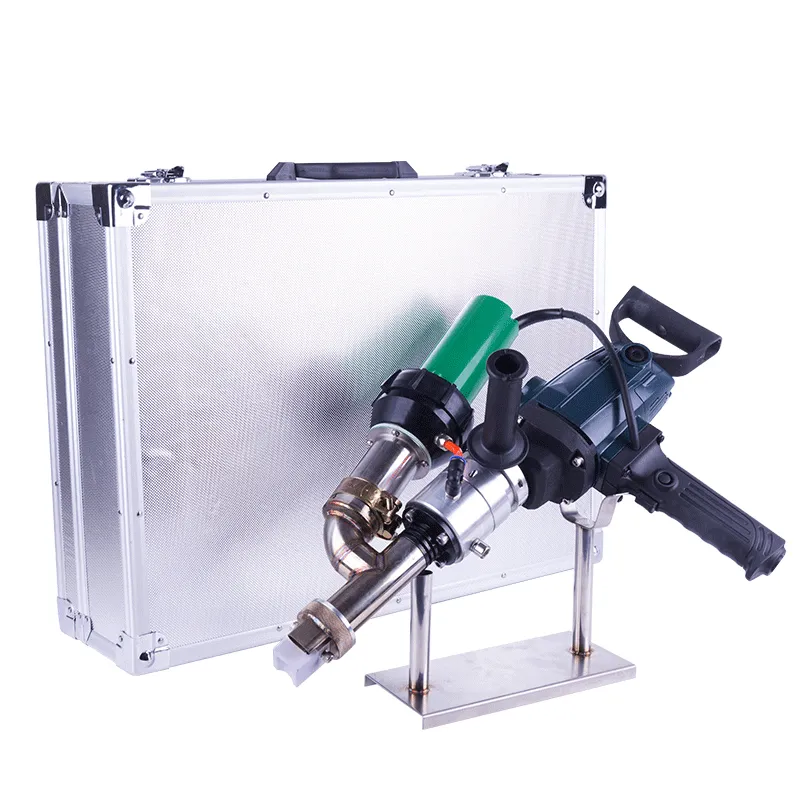

The development of a high-performance plastic extrusion welding machine, such as the SWT-NS600F, involves a meticulous multi-stage manufacturing process designed to ensure durability, precision, and operational reliability. Understanding this process underscores the engineering expertise embedded within these critical industrial tools.

1. Material Sourcing and Preparation:

High-grade materials are paramount. For robust mechanical components, manufacturers typically source aerospace-grade aluminum alloys and corrosion-resistant stainless steels (e.g., SS304, SS316). Electrical components utilize high-purity copper and specialized polymers for insulation, ensuring long-term electrical stability and safety. Heating elements are constructed from high-temperature resistant alloys like Inconel or Kanthal, essential for precise temperature control during welding. All incoming materials undergo stringent quality checks, often aligning with ISO 9001 standards for material traceability and composition verification.

2. Component Fabrication:

- Casting & Forging: Larger structural components, such as motor housings, gearboxes, and sections of the main chassis, are often produced via precision casting or forging. These methods impart superior mechanical strength and minimize internal defects.

- CNC Machining: Critical precision parts, including the extrusion screw, barrel, heating nozzle assemblies, feed systems, and control panel enclosures, are manufactured using advanced CNC (Computer Numerical Control) machining. This ensures exceptionally tight tolerances (e.g., ±0.01 mm), crucial for consistent melt delivery and welding performance.

- Electrical Assembly: Printed circuit boards (PCBs) for control systems are populated with industrial-grade microprocessors, sensors, and power management components. Wiring harnesses are custom-fabricated, utilizing shielded cables for EMI/RFI suppression, adhering to electrical safety standards such as UL or CE.

3. Assembly and Integration:

The various sub-assemblies—mechanical drives, heating systems, extrusion unit, and control electronics—are then meticulously integrated. This stage involves skilled technicians who ensure precise alignment and connection of all components. Special attention is paid to the thermal insulation of the heating zone to maximize energy efficiency and operator safety. Ergonomic design principles are applied to ensure comfortable and safe operation, reducing user fatigue.

4. Calibration and Testing:

Every finished extrusion welding machine undergoes rigorous calibration and testing protocols. This includes:

- Functional Testing: Verifying the operation of all mechanical and electrical systems, including motor speed, heating element performance, and air blower functionality.

- Temperature Uniformity Tests: Ensuring consistent and stable melt temperatures across the entire extrusion nozzle, critical for weld integrity. Data loggers often record temperature profiles to ensure adherence to specified ranges (e.g., ±2°C).

- Weld Strength Simulation: Performing test welds on various plastic materials (HDPE, PP, PVDF) and subjecting them to tensile strength tests according to ASTM D638 or ISO 527 standards. This validates the machine’s ability to produce welds that meet or exceed base material strength.

- Electrical Safety Tests: Dielectric strength (hi-pot) tests, ground continuity tests, and insulation resistance tests are performed in accordance with ANSI/UL 60745 or IEC 60745 standards to ensure operator safety.

5. Quality Assurance and Certification:

A final quality assurance check confirms adherence to all design specifications and performance benchmarks. Machines are typically certified with CE marking, indicating compliance with European health, safety, and environmental protection standards. Many reputable manufacturers also maintain ISO 9001 certification for their quality management systems, providing assurance of consistent product quality and continuous improvement. The service life of a well-maintained extruder welding machine can often exceed 10-15 years, particularly when constructed with durable materials and precision-engineered components.

Technical Specifications: SWT-NS600F Plastic Extrusion Welding Machine

The SWT-NS600F is an exemplary plastic extrusion welding machine designed for heavy-duty industrial applications. Its robust design and precise control systems ensure high-quality welds across various thermoplastic materials.

| Parameter | Specification |

|---|---|

| Welding Rod Diameter | Ø3.0mm – Ø5.0mm (standard) |

| Extrusion Output | Min. 2.0 kg/h (HDPE) / Max. 6.0 kg/h (HDPE) |

| Motor Power | 1600W Drive Motor + 1600W Hot Air Blower |

| Heating Power (Extrusion) | 800W (independent temperature control) |

| Temperature Range (Melt) | 200°C – 300°C (adjustable) |

| Pre-heating Temperature (Hot Air) | 20°C – 600°C (adjustable) |

| Weight | Approx. 7.0 kg (without rod) |

| Dimensions (L x W x H) | Approx. 450mm x 100mm x 300mm |

| Applicable Materials | HDPE, PP, PVDF, PE, PVC (with appropriate settings) |

| Control System | Digital display for temperature, programmable settings |

| Safety Features | Overload protection, overheat shutdown |

The precise control over melt temperature and pre-heating air flow ensures optimal molecular bonding, leading to welds that often exceed the strength of the parent material. The integrated hot air blower preheats the welding zone, ensuring proper surface preparation and enhanced fusion, a critical factor for achieving high-quality, homogeneous welds.

Application Scenarios and Target Industries

The versatility and robustness of plastic extrusion welders make them indispensable across a wide array of demanding industries. Their ability to create strong, leak-proof, and corrosion-resistant joints in thermoplastic materials is a critical advantage.

Target Industries:

- Petrochemical Industry: For welding large diameter HDPE pipes used in chemical transport, storage tanks, and geomembrane liners for containment ponds. The corrosion resistance of welded plastics significantly reduces maintenance and extends infrastructure lifespan compared to traditional metal alternatives.

- Water Supply & Drainage Systems: Essential for fabricating and repairing large-bore PE pipes in municipal waterworks, sewage treatment plants, and irrigation systems. The impermeability of extrusion welds prevents leakage and contamination, ensuring clean water delivery and efficient wastewater management.

- Environmental Engineering: Widely used in the construction of landfill liners, biogas plant components, and pollution control equipment. Geomembranes welded with an extruder welding machine provide a reliable barrier against hazardous waste and pollutants.

- Mining Sector: For lining tailings ponds, processing tanks, and constructing ventilation ducting from robust plastic materials. The durability of these welds withstands harsh operating conditions, including abrasive slurries and corrosive chemicals.

- Construction & Civil Engineering: Fabrication of custom plastic components for waterproofing, structural elements, and large-scale industrial container111s.

- Aquaculture: Construction and repair of large plastic fish tanks and ponds, ensuring watertight integrity.

Typical Application Scenarios:

- Geomembrane Welding: Critical for creating seamless, impervious liners for landfills, reservoirs, and secondary containment areas. The precise temperature control of a plastic extrusion welding machine ensures uniform melt and strong, homogeneous seams over vast areas.

- Pipe Fabrication: Joining sections of large-diameter HDPE and PP pipes, often encountered in industrial pipelines and municipal infrastructure. The ability to achieve full penetration welds is vital for high-pressure applications.

- Tank & Container Manufacturing: Constructing bespoke chemical storage tanks, water tanks, and ventilation ducts from thick plastic sheets. The high output of an extrusion welder significantly speeds up fabrication compared to hot air or hot plate welding.

- Repairs and Maintenance: On-site repair of damaged plastic structures, offering a reliable alternative to complete component replacement.

A key advantage in these scenarios is the energy saving potential. While the machine itself consumes power, the durability and corrosion resistance of the resulting plastic structures lead to significantly reduced maintenance, repair, and replacement costs over their extended service life, translating into substantial long-term operational savings.

Technical Advantages and Performance Metrics

Modern extrusion welding machines offer a suite of technical advantages that set them apart in the industrial fabrication landscape. These benefits translate directly into operational efficiency, cost savings, and superior product quality.

Key Advantages:

- Superior Weld Strength: Extrusion welding produces highly homogeneous and dense welds with excellent tensile and shear strength, often matching or exceeding the parent material’s properties. This is due to the volumetric fusion process where molten plastic is forced into the joint under pressure.

- High Output and Speed: Compared to hot air or hot plate welding, an extrusion welding machine can deposit significantly more material per hour, accelerating project timelines for large-scale fabrication. This high deposition rate is crucial for thick-walled pipes and large sheets.

- Versatility in Material Thickness: Capable of welding a wide range of material thicknesses, typically from 4mm up to 60mm or more, which makes them ideal for heavy-duty industrial applications where robust joints are critical.

- Precise Temperature Control: Advanced machines feature independent digital temperature controls for both the pre-heating air and the plastic melt. This precision ensures optimal molecular intermingling and minimizes material degradation, leading to consistent weld quality.

- Reduced Operator Skill Dependency: While skill is always beneficial, the automated feeding and controlled extrusion process reduce the variability associated with manual welding techniques, leading to more consistent results even with less experienced operators.

- Corrosion Resistance: Welded plastic structures offer inherent resistance to a vast array of chemicals and environmental factors, providing a long-lasting, maintenance-free solution where metallic components would quickly degrade. This is a significant advantage in petrochemical, wastewater, and marine applications.

Performance Metrics and Data:

To illustrate the performance capabilities, consider the following data points, often obtained from standardized testing (e.g., ISO 13953 for butt fusion joints):

- Tensile Strength: Welds produced by high-quality plastic extrusion welders often achieve >95% of the parent material’s tensile strength. For HDPE, this can translate to over 25 MPa.

- Elongation at Break: Weld zones typically retain excellent ductility, often exceeding 500% elongation for flexible plastics like HDPE, crucial for accommodating thermal expansion and ground movement without failure.

- Leakage Rate: For geomembrane applications, extrusion welds routinely achieve permeability rates of less than 1×10-14 m/s, ensuring impenetrable barriers.

- Energy Efficiency: Modern heating elements and optimized motor designs contribute to energy savings. For instance, a well-insulated extrusion barrel can reduce energy consumption by up to 15-20% compared to older designs, contributing to lower operational costs and a reduced carbon footprint.

Vendor Comparison and Customized Solutions

Selecting the right plastic extrusion welding machine and vendor is a critical decision that impacts project efficiency, weld quality, and long-term operational costs. A thorough comparison and understanding of customization options are essential.

Vendor Comparison Considerations:

| Feature | SWT-NS600F | Competitor Model X (Generic) |

|---|---|---|

| Extrusion Output (HDPE) | Up to 6.0 kg/h | Typically 3.0 – 5.0 kg/h |

| Motor & Blower Power | 1600W Drive + 1600W Hot Air | Often 1200W-1500W for each |

| Control System | Digital, programmable temp/speed | Analog or simpler digital controls |

| Weight (Portability) | Approx. 7.0 kg | Often heavier, 8-10 kg |

| Standard Nozzles | Flat, Corner, V-Groove | Basic flat nozzle, others extra |

| Certifications | CE, RoHS, ISO 9001 Manufacturing | May vary, sometimes limited to basic CE |

| After-sales Support | Comprehensive, parts availability | Potentially limited parts or service network |

Beyond raw specifications, consider the vendor’s reputation, years of service in the industry, availability of spare parts, and the quality of technical support. Authoritative references like ISO 9001 certifications for manufacturing processes and CE compliance are strong indicators of a trustworthy supplier. Client testimonials and case studies, such as successful installations for major petrochemical firms or public utility projects, further validate a vendor’s reliability and expertise.

Customized Solutions:

For specialized applications, off-the-shelf plastic extrusion welders may not always suffice. Leading manufacturers offer customized solutions to meet unique project requirements. This might include:

- Specialized Nozzles: Designing custom welding shoes and nozzles for intricate geometries, confined spaces, or specific joint configurations not covered by standard attachments.

- Automated Systems Integration: Integrating the extrusion welding unit into larger automated gantry systems for continuous welding of long seams in factory environments or for robotic applications.

- Material-Specific Optimizations: Fine-tuning heating profiles, screw designs, and motor parameters for optimal performance with niche thermoplastic materials beyond HDPE and PP, such as specialized fluoropolymers or high-temperature plastics.

- Enhanced Data Logging & Control: Implementing advanced control interfaces with comprehensive data logging capabilities for quality assurance and regulatory compliance, especially critical in regulated industries like pharmaceuticals or food processing.

These customized approaches ensure that the welding solution perfectly aligns with the operational demands and quality standards of even the most challenging projects.

Application Case Studies

Real-world applications demonstrate the tangible benefits and reliability of a high-quality extrusion welding machine. Here are a couple of examples highlighting its impact:

Case Study 1: Large-Scale Geomembrane Installation for a Landfill

A major waste management company was contracted to construct a new cell for a municipal solid waste landfill, requiring the installation of over 500,000 square meters of 2.0mm thick HDPE geomembrane liner. The project demanded continuous, high-integrity welds to ensure zero leakage and compliance with stringent environmental regulations (e.g., EPA standards). They deployed several SWT-NS600F plastic extrusion welders due to their high output (up to 6.0 kg/h) and consistent temperature control.

- Challenge: Covering a vast area with complex contours, requiring thousands of linear meters of high-quality, verifiable welds within a tight schedule.

- Solution: The SWT-NS600F machines were used for edge welding and detail work around sumps, pipe penetrations, and anchor trenches. The digital control system allowed operators to precisely set and maintain melt and pre-heat temperatures, crucial for achieving strong bonds in varying ambient conditions.

- Result: Over 99.8% of the welds passed non-destructive testing (air pressure testing) on the first attempt. Destructive peel and shear tests performed according to ASTM D6392 consistently showed weld strengths exceeding 98% of the parent material, ensuring long-term environmental protection. The project was completed two weeks ahead of schedule, attributing significant time savings to the efficiency and reliability of the extrusion welding equipment. Customer feedback highlighted the machines’ robust build quality and ease of use, even during extended operation shifts.

Case Study 2: Fabrication of Large Diameter HDPE Chemical Storage Tanks

A chemical processing plant needed to replace several aging steel storage tanks with new, corrosion-resistant HDPE tanks for storing aggressive acidic solutions. Each tank measured 5 meters in diameter and 8 meters in height, constructed from 25mm thick HDPE sheets. The fabrication required joining numerous curved and flat sections with strong, chemical-resistant welds.

- Challenge: Achieving full penetration welds on thick HDPE sheets, maintaining structural integrity, and ensuring chemical resistance against highly corrosive media.

- Solution: The fabricator utilized an SWT-NS600F extrusion welding machine equipped with custom-designed corner and fillet nozzles. The machine’s high torque motor and consistent extrusion pressure were critical for creating uniform, void-free welds in the thick material. Operators were trained to monitor weld parameters closely using the digital interface.

- Result: All tanks passed hydrostatic pressure testing (up to 1.5 times operating pressure) without any signs of leakage. Ultrasonic testing confirmed uniform weld profiles and an absence of internal defects. The chemical resistance of the welds was verified through accelerated aging tests, demonstrating integrity against 98% sulfuric acid. The projected service life of the HDPE tanks was estimated at 25-30 years, significantly exceeding the previous steel tanks’ lifespan, leading to substantial long-term cost savings in maintenance and replacement for the chemical plant.

These cases exemplify how advanced extrusion welding technology provides reliable, long-lasting solutions for critical industrial infrastructure.

Trustworthiness: FAQ, Lead Time, Warranty & Support

Building trust with B2B clients requires transparency and reliable commitments. Here’s a breakdown of essential information regarding the SWT-NS600F plastic extrusion welding machine and associated services.

Frequently Asked Questions (FAQ):

- Q: What materials can the SWT-NS600F weld?

A: The SWT-NS600F is optimized for HDPE, PP, and PVDF. With appropriate settings and welding rods, it can also be used for PE and PVC. - Q: What is the maximum thickness it can weld?

A: It is highly effective on materials ranging from 4mm up to 60mm, making it suitable for a broad spectrum of industrial applications. - Q: What kind of power supply is required?

A: The standard unit operates on a single-phase 220-240V AC, 50/60Hz power supply, requiring a dedicated circuit with appropriate amperage (typically 20A minimum). - Q: Are spare parts readily available?

A: Yes, critical wear parts like heating elements, screws, and nozzles are kept in stock and can be shipped globally within short lead times. - Q: Is training available for operators?

A: We offer comprehensive operator training programs, either on-site or at our facilities, covering machine operation, maintenance, and best welding practices to ensure optimal performance and safety.

Lead Time & Fulfillment:

Standard models of the SWT-NS600F plastic extrusion welders typically have a lead time of 2-4 weeks from order confirmation, subject to current stock levels and production schedules. For customized solutions or large-volume orders, lead times will be provided on a project-specific basis, usually ranging from 6-10 weeks. We maintain robust supply chain management to ensure timely delivery and efficient logistics globally, utilizing trusted freight partners to guarantee secure transit.

Warranty Commitments:

The SWT-NS600F comes with a standard 12-month limited warranty covering manufacturing defects and material failures from the date of purchase. Extended warranty options are available for enhanced peace of mind. Our warranty policy is transparent and designed to ensure customer satisfaction and protect your investment.

Customer Support & After-Sales Service:

Our commitment extends beyond the sale. We provide comprehensive after-sales support including:

- Technical Assistance: A dedicated team of experienced engineers is available via phone and email to troubleshoot issues and provide expert guidance.

- Spare Parts & Consumables: Easy access to genuine spare parts and welding rods through our global distribution network.

- Maintenance Services: On-site or remote diagnostic and maintenance services to ensure peak performance and extend the lifespan of your equipment.

- Documentation: Comprehensive operation manuals, maintenance guides, and technical drawings are provided with each machine.

Our global network of authorized service partners ensures that expert support is never far away, minimizing downtime and maximizing productivity for our clients.

References

- ASTM International. “Standard Test Method for Tensile Properties of Plastics” (ASTM D638).

- ISO (International Organization for Standardization). “Plastics pipes and fittings – Test method for the resistance to rapid crack propagation – Full-notch Charpy test (FNC)” (ISO 13479).

- ISO (International Organization for Standardization). “Plastics pipes and fittings – Procedures for the assessment of the strength of pipe butt fusion joints” (ISO 13953).

- European Committee for Standardization (CEN). “Welding of thermoplastics – Hot gas extrusion welding of pipes and fittings” (EN 13067).

- Hage, D. E. (2018). “Polymer Welding: Technologies and Applications.” CRC Press.

MM-Tech, established in 2011, is a leading manufacturer of thermoplastic welding equipment in China.hot air plastic welder We specialize in the research, development, production, and sales of thermoplastic welding equipment.hot air welding gun Our product line is extremely rich, covering geomembrane welders, polymer hot air welders, tarpaulin hot air welders, hot air welders, hand extrusion welders, and various welding tools, comprehensively meeting the diverse needs of both on-site construction and workshop operations.hot air welder roofing Our products have been exported to over 100 countries and have won the trust of more than 3,000 customers.plastic welding heat gun|super blog