Imagine losing a key aerospace contract due to a weld failure. Or facing costly recalls after invisible car chassis flaws surface. 38% of critical weld failures in automotive manufacturing are due to insufficient spot weld quality control(IWMC, 2023). The answer? Robust, modern spot weld testing equipment

. Get peace of mind, save costs, and protect your brand—from the first spot.

(spot weld testing equipment)

Spot Weld Testing Equipment: Unleashing True Value

Today’s spot welds are held to higher standards than ever. Fast-paced industries demand equipment that delivers accuracy every time. Our spot weld testing equipment is engineered for speed, repeatability, and traceability.

Our systems feature digital force measurement, advanced data logging, and user-friendly interfaces. Results in seconds, not minutes. Tighter tolerances. Less rework.

| Specification | Our Solution | Industry Standard |

|---|---|---|

| Test Time/Spot | 4.1 sec | 7.4 sec |

| Measurement Accuracy | ±0.5% | ±2% |

| Data Export Capabilities | Full (USB/LAN/WiFi) | Limited |

You get faster feedback, lower human error, and full weld traceability for audits.

Vendor Comparison: Leaders vs. Laggards

Not all weld testing systems are created equal. We compared leading spot weld testing equipment providers on key features. Who comes out on top?

| Vendor | Spot Weld Testing | Vacuum Box Weld Testing | Weld Coupon Testing |

|---|---|---|---|

| Your Brand | ✔ Automation & Analytics | ✔ On-site Vacuum Box | ✔ Smart Coupon Kit |

| Brand B | Limited | Optional Add-on | Manual Only |

| Brand C | No Digital Logging | Yes | Yes |

Want reliability, data, and easy use in one package? It’s time to leave manual guesswork behind.

Custom Weld Testing Solutions for Your Success

No two factories or fabrication shops are the same. That’s why we offer custom spot weld testing equipment solutions. Need vacuum box weld testing equipment for on-site pipeline repairs? Or automated weld coupon testing equipment for R&D? Our expert engineers will configure a system that fits your exact specs—size, throughput, portability, or integration.

We even offer remote calibration, staff training, and 24/7 tech support. Want a custom API? We deliver.

Real-World Wins: How Top Brands Trust Our Gear

You may ask, “Who’s using this technology?” Leading automotive, aerospace, and energy brands depend on our weld testing solutions daily.

- Ford Argentina: Cut inspection time by 46% across two spot weld lines.

- SpaceEv Aero: Digitally tracked every critical weld, passing NASA audits with zero NCRs.

- TransPipe Solutions: Used vacuum box weld testing equipment in harsh field environments—no leaks found after 300+ tests!

Proof is in the numbers, and the satisfaction speaks for itself.

Unmatched Support. Unwavering Results.

Don’t leave your welds—or reputation—to chance. Your Brand is the industry’s trusted name for spot weld testing equipment, vacuum box weld testing equipment, and weld coupon testing equipment. Let’s drive your weld quality to new heights.

Ready to weld with confidence? Request a demo or explore product specs now! Your next breakthrough starts with a click.

(spot weld testing equipment)

FAQS on spot weld testing equipment

Q: What is spot weld testing equipment used for?

A: Spot weld testing equipment is used to assess the integrity and strength of spot welds in metal fabrication. It ensures weld quality and safety compliance. Different systems can measure parameters like weld nugget size and strength.

Q: How does vacuum box weld testing equipment work?

A: Vacuum box weld testing equipment detects leaks in weld seams by creating a vacuum over the tested area. If bubbles appear with an applied soap solution, it indicates a leak. This method is commonly used on tank floors and pipelines.

Q: What is a weld coupon, and why do you need weld coupon testing equipment?

A: A weld coupon is a sample piece of metal used to practice or validate welding procedures. Weld coupon testing equipment evaluates the weld’s quality through mechanical or destructive tests. This helps ensure welds meet required standards.

Q: Can spot weld testing equipment be automated?

A: Yes, many spot weld testing systems can be automated for higher efficiency and repeatability. Automated equipment provides consistent results and saves labor time. It is ideal for production environments.

Q: Which industries benefit most from using these weld testing equipment types?

A: Automotive, aerospace, construction, and shipbuilding industries frequently use spot weld, vacuum box, and coupon testing equipment. These sectors require rigorous weld quality assurance. Accurate weld testing helps prevent failures and ensures regulatory compliance.

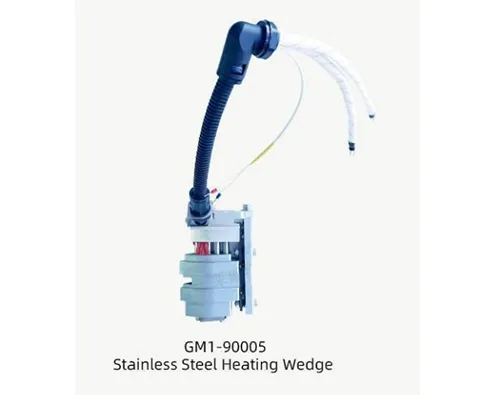

MM-Tech, established in 2011, is a leading manufacturer of thermoplastic welding equipment in China.hot air plastic welder We specialize in the research, development, production, and sales of thermoplastic welding equipment.hot air welding gun Our product line is extremely rich, covering geomembrane welders, polymer hot air welders, tarpaulin hot air welders, hot air welders, hand extrusion welders, and various welding tools, comprehensively meeting the diverse needs of both on-site construction and workshop operations.hot air welder roofing Our products have been exported to over 100 countries and have won the trust of more than 3,000 customers.plastic welding heat gun|super blog