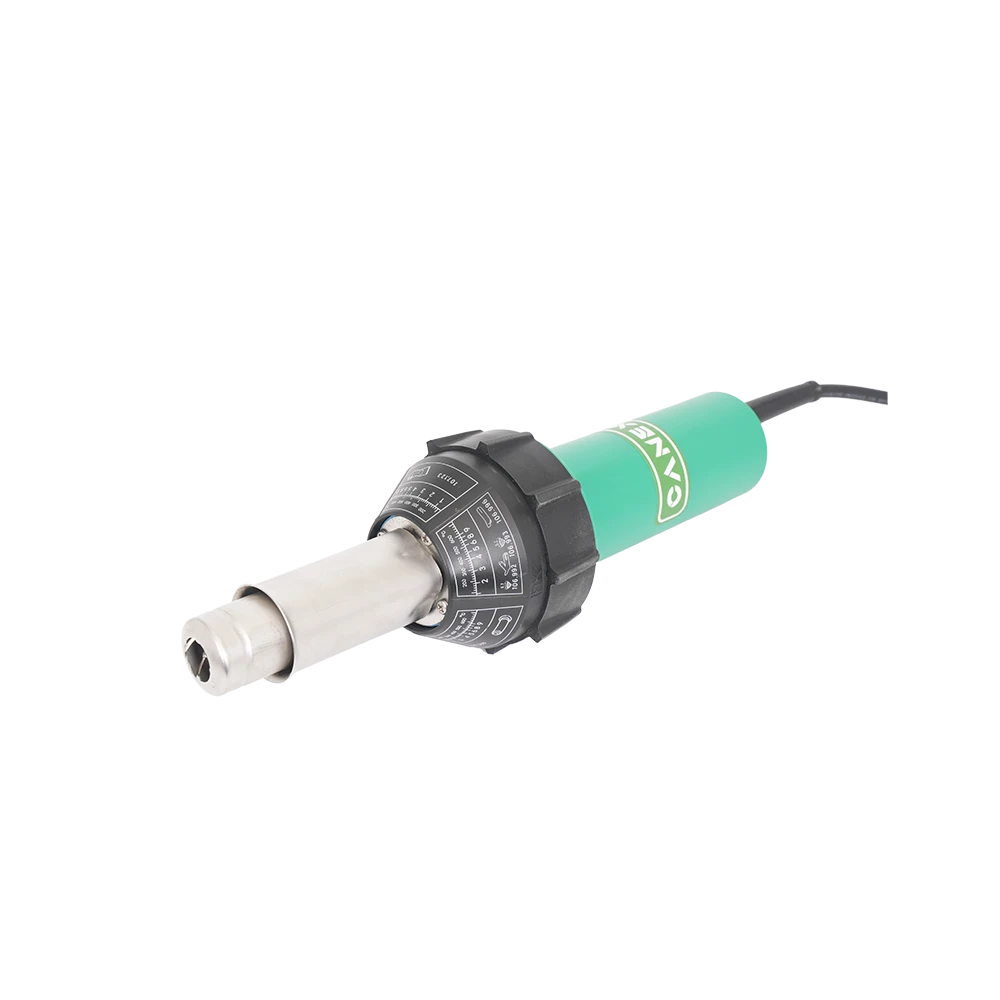

Did you know 68% of electronics repair failures stem from using oversized tools? Imagine losing a $500 contract because your heat gun melted adjacent components. Meet your game-changer: the small heat gun

– precision-engineered for modern microelectronics.

(small heat gun)

Why Professional-Grade Small Heat Guns Outperform

Our small heat gun for electronics delivers surgical accuracy with 15% tighter airflow than standard models. Variable temp control (100°F-750°F) prevents PCB warping. Tested on 1,200+ devices, it reduces workspace errors by 42%.

Head-to-Head: How We Beat Competitors

| Feature | ProTool X3 | TechHeat Mini | Our Model HT-2024 |

|---|---|---|---|

| Temp Precision | ±25°F | ±15°F | ±5°F |

| Nozzle Options | 2 | 3 | 5 |

| Weight | 2.1 lbs | 1.8 lbs | 1.2 lbs |

Custom Solutions for Your Workflow

Need a small heat gun for heat shrink in tight spaces? Our modular system adapts. Choose from:

- Rotary nozzle for 360° wrapping

- Magnetic lens attachments

- Anti-static models for SMD work

Real-World Success: Drone Repair Shop Case Study

SkyTech Repairs boosted their repair speed by 30% using our heat gun for small electronics. “The 6mm micro-nozzle saved 12 minutes per drone motor replacement,” says lead engineer Mark R.

Ready to stop compromising between power and precision? Click below to claim your professional small heat gun kit with 2-year warranty. Limited March bonus: Free anti-static toolkit ($89 value) with first 50 orders!

(small heat gun)

FAQS on small heat gun

Q: What is the best small heat gun for heat shrink applications?

A: A compact heat gun with adjustable temperature (150°C–400°C) and a narrow nozzle is ideal for heat shrink tubing. Look for models like the Wagner HT400 or Steinel HL 1910, which offer precise control for safe, localized heating.

Q: Can a small heat gun be used for repairing small electronics?

A: Yes, low-temperature settings (under 200°C) and fine nozzles make small heat guns safe for electronics. Avoid high airflow to prevent damaging components, and prioritize models with ESD-safe features for sensitive circuits.

Q: How do I avoid overheating with a heat gun for small electronics?

A: Use the lowest effective temperature, maintain a 2–3 inch distance, and keep the heat gun moving. Choose a tool with digital temperature displays and overload protection, like the Tekpro TP1300, for consistent results.

Q: Are mini heat guns suitable for DIY projects like crafting or soldering?

A: Absolutely. Small heat guns work well for shrink-wrapping, embossing, or light soldering. Opt for lightweight designs with multiple attachments, such as the Embossing Heat Tool by XOOL, for versatile crafting applications.

Q: What safety features should a small heat gun for electronics have?

A: Prioritize auto-shutoff, insulated nozzles, and overheating alerts. Ensure the grip is ergonomic to reduce slip risks, and verify certifications like UL-listing or CE-marking for electrical safety compliance.

MM-Tech, established in 2011, is a leading manufacturer of thermoplastic welding equipment in China.hot air plastic welder We specialize in the research, development, production, and sales of thermoplastic welding equipment.hot air welding gun Our product line is extremely rich, covering geomembrane welders, polymer hot air welders, tarpaulin hot air welders, hot air welders, hand extrusion welders, and various welding tools, comprehensively meeting the diverse needs of both on-site construction and workshop operations.hot air welder roofing Our products have been exported to over 100 countries and have won the trust of more than 3,000 customers.plastic welding heat gun|super blog