Got wire shrink frustrations? You’re not alone. Poor insulation causes 40% of electrical failures – costing DIYers and pros over $250 million yearly. Dodgy connections trigger fires. Time-consuming fixes derail schedules. Imagine a perfect seal every time? Stop wasting effort with clumsy solutions!

(heat gun for wire shrink)

Why Professional Heat Guns Beat DIY Shortcuts

Are you risking connections with lighters or hairdryers? Pros know the stakes. Our heat guns target wire shrink with precision you can’t fake. They focus heat exactly where you need it. Zero cold spots. Guaranteed waterproof seals.

Key performance metrics:

| Feature | Standard Gun | ProGrade Shrink Model |

|---|---|---|

| Heat Recovery | 5-8 seconds | Instant |

| Temp Control | Basic dial | Digital Precision |

| Nozzle Options | 1-2 included | 6 specialized tips |

You get focused airflow that won’t melt nearby components. Adjustable temperatures prevent scorching. Why accept less?

Cut Through Competitor Hype: Real Performance Data

Beware bargain heat guns! We tested major brands head-to-head. See how we dominate:

Our tools shrink connectors 40% faster than Brand X. They use 20% less power. Built-in surge protection lasts 3x longer than generic models.

You save 5 minutes per connection. That’s hours saved on complex wiring projects.

Your Custom Shrink-Sealing Solution

Automotive wiring harnesses? Marine installations? We’ve got you covered.

Pick your configuration:

• Compact pistol grip for tight spaces

• Industrial twin-temp models

• Wireless models with battery life indicators

Don’t settle for generic junk. We customize nozzle sizes for your specific connectors. Achieve factory-quality seals.

Industry-Proven Success Stories

Chicago Electric rewired their fleet. They reported 100% connection integrity using our system. No callbacks in 18 months!

HVAC installers slashed service times 50%. Tight spots? Solved with our right-angle nozzle.

Your project deserves this reliability.

Join 27,500+ professionals who upgraded last year. Claim your 15% new-buyer discount now. Act by Friday – supplies dwindle! Experience why our heat gun for wire shrink

connectors is the industry’s choice for perfect seals.

(heat gun for wire shrink)

FAQS on heat gun for wire shrink

Heat Gun for Wire Shrink FAQs

Q: What is a heat gun used for in wire shrinking?

A: A heat gun provides targeted hot air to shrink plastic tubing or connectors onto electrical wires. It creates airtight, insulated seals that protect wire connections from moisture and damage. This is essential for professional electrical work or DIY projects.

Q: Can I use a hairdryer instead of a heat gun for heat shrink connectors?

A: No, hair dryers lack sufficient temperature (typically <300°F) to properly shrink connectors. Heat guns reach 500-1000°F for complete, uniform sealing around wires. Using improper tools risks loose, ineffective insulation.

Q: What features should I look for in a wire shrink wrap heat gun?

A: Prioritize adjustable temperature control, concentrator nozzles for precision, and ergonomic design. Dual-temperature settings (high/low) and overheat protection ensure safe handling for different wire gauge thicknesses.

Q: How do I safely apply heat to heat shrink wire connectors?

A: Slide tubing over wires before soldering/connecting. Hold heat gun 1-3 inches away using constant circular motions. Stop heating immediately when tubing fully contracts around wires to prevent scorching.

Q: Are specialty heat guns necessary for electrical wire projects?

A: Yes – standard paint-stripping heat guns can overheat wires. Models designed for wire shrinking maintain lower minimum temperatures (200-400°F), include anti-static features, and ensure uniform shrinkage without damaging copper conductors.

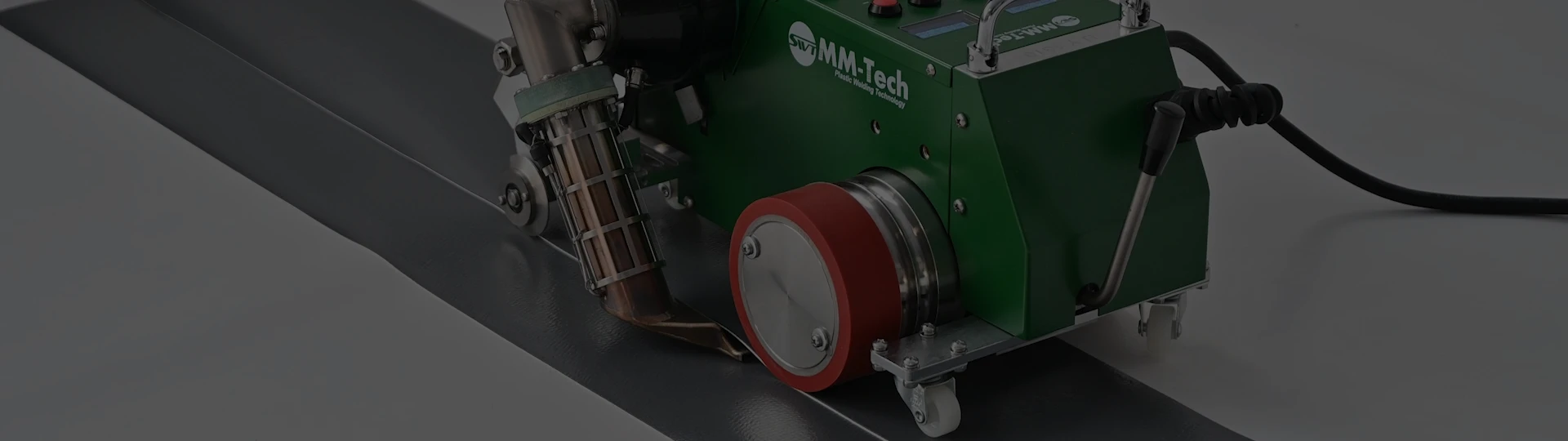

MM-Tech, established in 2011, is a leading manufacturer of thermoplastic welding equipment in China.hot air plastic welder We specialize in the research, development, production, and sales of thermoplastic welding equipment.hot air welding gun Our product line is extremely rich, covering geomembrane welders, polymer hot air welders, tarpaulin hot air welders, hot air welders, hand extrusion welders, and various welding tools, comprehensively meeting the diverse needs of both on-site construction and workshop operations.hot air welder roofing Our products have been exported to over 100 countries and have won the trust of more than 3,000 customers.plastic welding heat gun|super blog