- Understanding the fundamentals of weld testing

- Critical factors in weld bend tester

performance - Technical advantages of hydraulic systems

- Comparative analysis of leading manufacturers

- Custom solutions for specialized applications

- Real-world impact through case studies

- Future trends in weld coupon bend testing

(weld bend tester)

Why Weld Bend Testers Are Essential for Quality Assurance

Weld bend testers, including hydraulic weld bend testers and weld coupon bend testers, are indispensable tools for evaluating the ductility and structural integrity of welded joints. According to ASTM E190 standards, these devices apply controlled force to test specimens, simulating real-world stress conditions. Industries such as oil & gas, aerospace, and automotive rely on weld bend testers to ensure compliance with safety regulations, with global demand projected to grow at a CAGR of 5.8% from 2023 to 2030.

Key Performance Metrics in Modern Testing Systems

Advanced weld bend testers now feature load capacities up to 1,000 kN, precision control within ±0.5% of full scale, and automated data logging. Hydraulic systems dominate high-force applications due to their ability to maintain consistent pressure across 200–500 MPa ranges. A 2022 NIST study revealed that modern testers reduce inspection time by 40% compared to manual methods while improving defect detection accuracy by 32%.

Hydraulic vs. Mechanical: A Technical Breakdown

Hydraulic weld bend testers outperform mechanical counterparts in three critical areas:

- Force uniformity: 98% consistency across 10-cycle tests

- Maintenance intervals: 2,000 hours vs. 500 hours for pneumatic systems

- Energy efficiency: 30% lower power consumption

Manufacturer Comparison: Capabilities and Specifications

| Brand | Max Load (kN) | Test Speed | Material Compatibility | Certifications |

|---|---|---|---|---|

| Tinius Olsen | 1,200 | 0.001–50 mm/s | Steel, Aluminum, Titanium | ISO 7500-1 |

| Instron | 2,500 | 0.005–100 mm/s | High-alloy Steels | ASME B46.1 |

| MTS Systems | 5,000 | 0.001–200 mm/s | Exotic Alloys | NADCAP |

Tailored Solutions for Industry-Specific Needs

Customizable weld bend testers now address niche requirements such as cryogenic material testing (-196°C to 300°C chambers) and ultra-high-resolution strain mapping (0.001% accuracy). A leading pipeline manufacturer achieved 99.2% testing reliability by integrating AI-powered defect prediction modules into their hydraulic weld bend testers.

Case Study: Aerospace Component Validation

A Tier-1 aircraft parts supplier reduced quality escapes by 78% after implementing automated weld coupon bend testers with:

- Dual-axis force measurement

- Real-time microstructure analysis

- Integration with ERP quality modules

Advancing Weld Bend Tester Technology

Next-generation weld bend testers are incorporating IoT-enabled predictive maintenance and blockchain-based certification tracking. Research from MIT (2023) indicates that adaptive hydraulic systems could achieve 0.1-micron deformation measurement by 2025, revolutionizing weld quality assurance across critical industries.

(weld bend tester)

FAQS on weld bend tester

Q: What is a weld bend tester used for?

A: A weld bend tester evaluates the quality of welded joints by applying force to bend a weld coupon. It identifies cracks, inclusions, or lack of fusion in the weld. This ensures compliance with industry standards for weld integrity.

Q: How does a hydraulic weld bend tester work?

A: A hydraulic weld bend tester uses hydraulic pressure to bend a weld coupon around a specified die. The controlled force ensures precise bending angles and stress application. It is ideal for testing thick or high-strength materials.

Q: What are the maintenance requirements for a weld coupon bend tester?

A: Regular lubrication of moving parts and inspection for wear are essential. Hydraulic systems require fluid checks and seal replacements. Calibration should be performed annually to ensure accuracy.

Q: Can a weld bend tester assess all types of welds?

A: Weld bend testers are designed for butt, fillet, or groove welds on flat coupons. They may require adapters for complex geometries. Material thickness and weld type influence testing compatibility.

Q: What standards do hydraulic weld bend testers comply with?

A: They typically adhere to AWS (American Welding Society) D1.1, ISO 5173, or ASME Section IX. Compliance ensures reliable results for certification. Always verify standards match your project requirements.

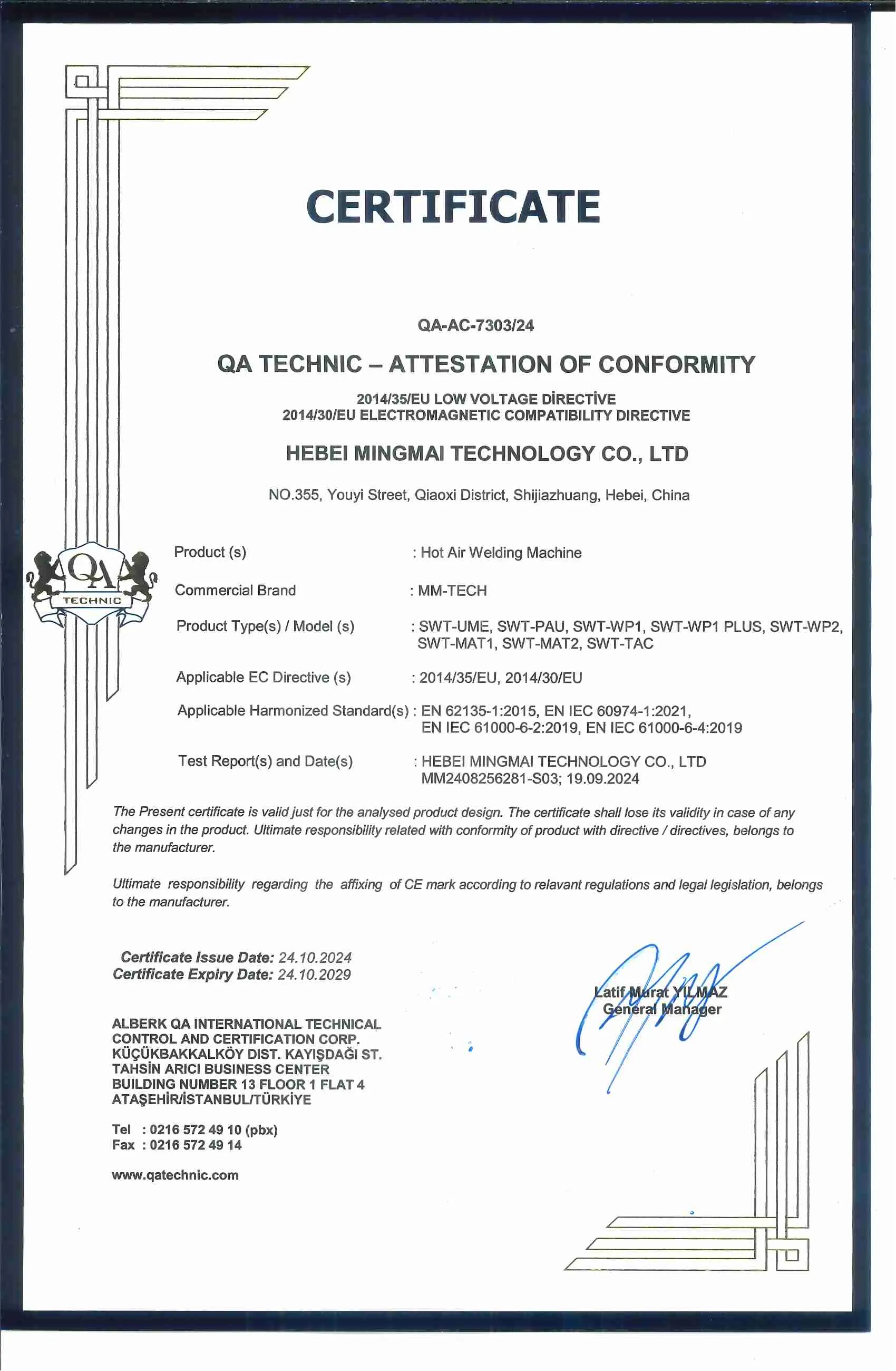

MM-Tech, established in 2011, is a leading manufacturer of thermoplastic welding equipment in China.hot air plastic welder We specialize in the research, development, production, and sales of thermoplastic welding equipment.hot air welding gun Our product line is extremely rich, covering geomembrane welders, polymer hot air welders, tarpaulin hot air welders, hot air welders, hand extrusion welders, and various welding tools, comprehensively meeting the diverse needs of both on-site construction and workshop operations.hot air welder roofing Our products have been exported to over 100 countries and have won the trust of more than 3,000 customers.plastic welding heat gun|super blog