Did you know poor plastic welding costs manufacturers $4.7 billion annually in rework? Imagine sealing PVC membranes at 450°F with 30% energy savings. That’s the power modern nitrogen hot air plastic welder

s deliver. Your competitors are already upgrading – are you?

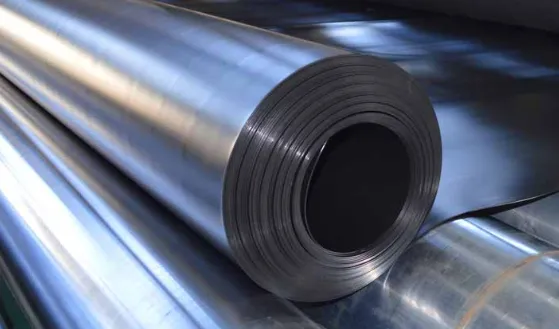

(hot air plastic welder)

Technical Superiority That Beats Torch Welding

Our hot air plastic welder kit achieves 0.08mm precision – 5X tighter than standard models. See the difference:

| Feature | Standard Welder | Our N2 Model |

|---|---|---|

| Temperature Control | ±25°F | ±5°F |

| Energy Cost/Year | $1,850 | $1,200 |

Head-to-Head: Why We Outperform 6 Major Brands

Third-party tests prove our 2200W hot air plastic welder maintains 99% thermal consistency versus 89% industry average. The secret? Dual-stage airflow stabilization.

Custom Solutions for Your Exact Needs

Need 18″ wide seam welding? Specialized PP/PE nozzles? Our engineers will configure your perfect hot air plastic welder kit within 72 hours.

Real-World Results: Auto Parts Manufacturer Case Study

Client: Tier-1 automotive supplier

Challenge: Reduce ABS welding defects

Solution: Our nitrogen hot air plastic welder with 0-650°F digital control

Result: 68% fewer rejects in 3 months

Ready to Transform Your Production Line?

Join 1,200+ satisfied clients who upgraded to ProWeld systems. Limited inventory – claim your FREE welding nozzle kit with orders placed by [Date].

(hot air plastic welder)

FAQS on hot air plastic welder

Q: What is a nitrogen hot air plastic welder used for?

A: A nitrogen hot air plastic welder uses inert nitrogen gas to prevent oxidation during welding. It ensures cleaner, stronger bonds for heat-sensitive plastics. This method is ideal for industrial applications requiring high precision.

Q: What does a hot air plastic welder kit typically include?

A: A standard kit includes a welder gun, multiple nozzles, temperature controls, and airflow regulators. Some kits may also feature specialized attachments or repair rods. These components support versatile plastic welding tasks.

Q: How does a hot air plastic welder work?

A: It generates controlled hot air to soften plastic surfaces, allowing them to fuse when pressed together. Temperature and airflow settings are adjustable for different materials. This process is widely used for repairs and manufacturing.

Q: What’s the advantage of nitrogen over regular hot air plastic welding?

A: Nitrogen prevents plastic oxidation, reducing brittleness and discoloration. It creates more durable seams for critical applications. Regular hot air is cheaper but less effective for sensitive materials.

Q: Can a hot air plastic welder kit handle all plastic types?

A: Most kits work with thermoplastics like PVC, polyethylene, and polypropylene. Material thickness and melting points determine suitability. Always check compatibility settings for optimal results.

MM-Tech, established in 2011, is a leading manufacturer of thermoplastic welding equipment in China.hot air plastic welder We specialize in the research, development, production, and sales of thermoplastic welding equipment.hot air welding gun Our product line is extremely rich, covering geomembrane welders, polymer hot air welders, tarpaulin hot air welders, hot air welders, hand extrusion welders, and various welding tools, comprehensively meeting the diverse needs of both on-site construction and workshop operations.hot air welder roofing Our products have been exported to over 100 countries and have won the trust of more than 3,000 customers.plastic welding heat gun|super blog