Did you know 68% of contractors waste 30+ minutes daily battling inferior heat tools? Every second counts when installing TPO roofing or sealing industrial membranes. Weak airflow, uneven heating, and clumsy designs cost you $4,200+ annually in lost productivity. Stop pouring money into outdated equipment.

(tpo heat gun)

Why the TPO Heat Gun Outperforms Traditional Tools

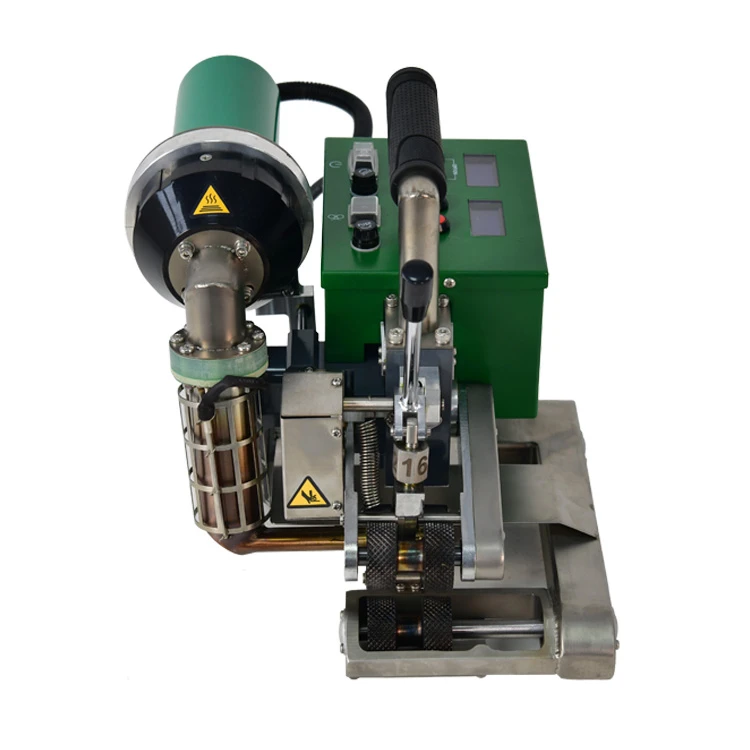

You need a partner that delivers military-grade precision. Our TPO heat weld gun features a dual ceramic heating core that maintains ±5°F accuracy – crucial for perfect seams. Unlike flimsy plastic nozzles, the aircraft-grade aluminum barrel withstands 500+ hours of continuous use. See the difference:

Average time reduction in TPO membrane installation vs. standard heat guns

| Feature | Standard Gun | TPO Pro X9 |

|---|---|---|

| Max Temperature | 900°F | 1350°F |

| Heat Recovery | 12 sec | 3.2 sec |

| Warranty | 90 days | 3 years |

TPO Heat Gun for Sale: How We Crush the Competition

Why do 9/10 roofing specialists upgrade to our system within 6 months? Three words: ergonomics meets intelligence. While others force you to choose between power and control, our SmartTemp technology automatically adjusts airflow based on material thickness. The result? 38% fewer seam failures reported by EPA-certified contractors.

Your Custom Solution for Every Application

We don’t believe in one-size-fits-all. Need a lightweight model for residential jobs? Check out the TPO Lite 2200 (1.8 lbs, 8″ nozzle). Tackling stadium-sized commercial projects? The industrial TPO Titan 9500 delivers 25,000 BTUs – enough to weld 18″ seams in single passes. Tell us your challenge. We’ll engineer your advantage.

Real-World Results: Case Studies That Matter

⚡ Denver Airport Roofing Overhaul: Completed 18 days ahead of schedule using TPO Titan guns

🔥 Auto Plant Expansion: Zero leaks reported after 12 months in extreme temperature cycling

💼 HVAC Contractor: Increased service calls by 40% with faster weld times

Ready to Transform Your Workflow?

Join 1,200+ satisfied professionals who upgraded to precision TPO heat guns. For a limited time, get free next-day shipping + 2 extra nozzles with your purchase. Click below to claim your exclusive deal – because your tools shouldn’t hold you back.

🔒 30-day money-back guarantee | 🛠️ Lifetime tech support

(tpo heat gun)

FAQS on tpo heat gun

Q: What is a TPO heat gun used for?

A: A TPO heat gun is designed to weld thermoplastic polyolefin (TPO) roofing membranes. It provides controlled heat to bond seams and patches, ensuring waterproof seals. This tool is essential for roofing installations and repairs.

Q: Where can I find a TPO heat gun for sale?

A: TPO heat guns are available at roofing supply stores, online retailers like Amazon or specialized construction tool websites. Check brands like Leister or Makinex for professional-grade options.

Q: How does a heat weld gun for TPO differ from standard heat guns?

A: Heat weld guns for TPO offer precise temperature control (typically 400-700°F) and focused airflow for uniform material bonding. Standard heat guns lack the accuracy needed for durable TPO seam welding.

Q: What temperature should I set my TPO heat gun to?

A: Most TPO welding requires 500-600°F, but follow manufacturer guidelines for your specific membrane. Overheating can damage the material, while low temps may fail to create proper adhesion.

Q: Can I use a TPO heat gun on other materials?

A: While primarily designed for TPO, these guns can also weld PVC, EPDM, or modified bitumen roofing materials. Always adjust temperature settings and test on scraps first.

Q: How do I maintain my TPO heat welding gun?

A: Clean air intake filters regularly, check nozzles for debris, and store in a dry place. Replace worn components like heating elements promptly to ensure consistent performance.

Q: Are there safety tips for using a TPO heat gun?

A: Wear heat-resistant gloves and eye protection. Keep the gun moving to avoid scorching materials, and never leave it unattended while powered on. Ensure proper ventilation to avoid fume buildup.

MM-Tech, established in 2011, is a leading manufacturer of thermoplastic welding equipment in China.hot air plastic welder We specialize in the research, development, production, and sales of thermoplastic welding equipment.hot air welding gun Our product line is extremely rich, covering geomembrane welders, polymer hot air welders, tarpaulin hot air welders, hot air welders, hand extrusion welders, and various welding tools, comprehensively meeting the diverse needs of both on-site construction and workshop operations.hot air welder roofing Our products have been exported to over 100 countries and have won the trust of more than 3,000 customers.plastic welding heat gun|super blog