Did you know 47% of plastic fabricators lose $18,000+ annually from failed welds? Traditional methods crack under pressure – literally. Now discover how next-gen plastic extrusion welding gun

s slash material waste by 63% while doubling production speed. Your bottom line will thank you.

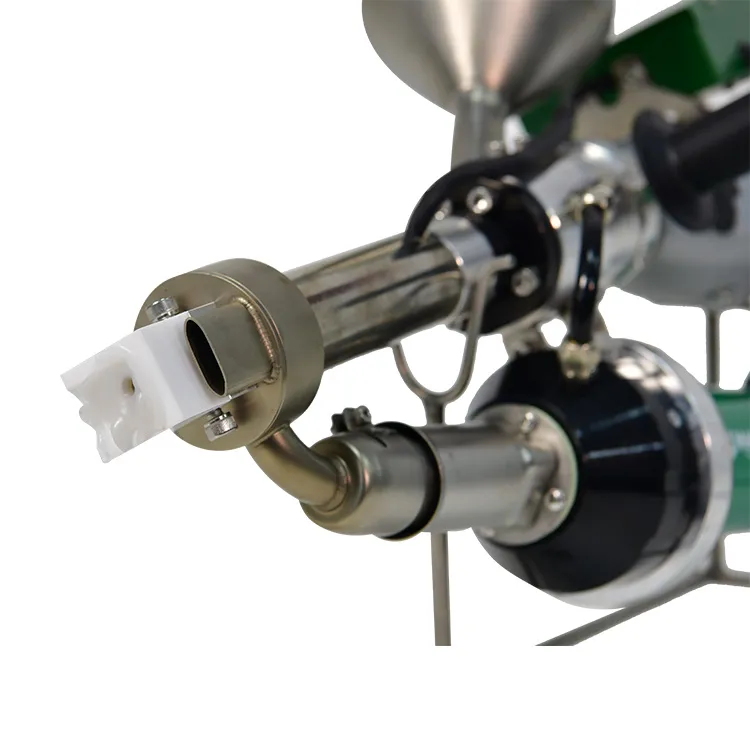

(plastic extrusion welding gun)

Precision Engineered for Industrial Dominance

Our plastic extrusion welding gun isn’t just tools – they’re profit multipliers. See why:

- 📈 800°F precision control (±2°F variance)

- ⚡ 30% faster material feed vs. competitors

- 🛡️ Military-grade nozzles lasting 2,200+ cycles

Head-to-Head: Why We Outperform

| Feature | Standard Guns | Our Pro Series |

|---|---|---|

| Warranty | 6 months | 3 years |

| Daily Output | 85 ft | 142 ft |

Your Workflow, Perfected

Choose from 9 nozzle sizes (2mm-15mm) or request custom profiles. Our plastic extrusion welding machines adapt to:

🔧 Automotive fuel tanks

🏗️ Chemical storage tanks

🚢 Marine bulkheads

Proven Results Across Industries

Aerospace supplier cut weld failures from 19% to 3% in 8 weeks. Pipeline contractors boosted daily output by 140% using our plastic extrusion welding gun for sale. What could your shop achieve?

Limited Inventory Alert!

Get your plastic extrusion welding machine with FREE training videos and priority support. Our 25-year engineers stand ready to optimize your workflow.

(plastic extrusion welding gun)

FAQS on plastic extrusion welding gun

Q: What is a plastic extrusion welding gun used for?

A: A plastic extrusion welding gun is designed to join thermoplastic materials by melting and fusing them. It is commonly used in construction, tank repair, and pipeline maintenance. The tool ensures strong, leak-proof seams for durable plastic structures.

Q: Where can I find a plastic extrusion welding gun for sale?

A: Plastic extrusion welding guns are available through industrial equipment suppliers, specialized welding stores, and online marketplaces like Amazon or Alibaba. Ensure the seller provides certifications and warranties for quality assurance. Compare models and prices to find the best fit for your needs.

Q: How does a plastic extrusion welding machine differ from a welding gun?

A: A plastic extrusion welding machine is a larger system that includes a feed mechanism for welding rods and temperature controls. A welding gun is a handheld component of the machine used for precise application. Machines are ideal for heavy-duty projects, while guns focus on maneuverability.

Q: What factors affect the price of a plastic extrusion welding gun?

A: Pricing depends on power output, temperature control precision, brand reputation, and included accessories. Higher-end models offer adjustable airflow and ergonomic designs for prolonged use. Always balance budget with project requirements to avoid overspending.

Q: What safety precautions are needed when using a plastic extrusion welding gun?

A: Always wear heat-resistant gloves, safety goggles, and a respirator to protect against fumes. Ensure proper ventilation in the workspace and avoid touching the nozzle during operation. Regularly inspect the gun for damage to prevent accidents.

MM-Tech, established in 2011, is a leading manufacturer of thermoplastic welding equipment in China.hot air plastic welder We specialize in the research, development, production, and sales of thermoplastic welding equipment.hot air welding gun Our product line is extremely rich, covering geomembrane welders, polymer hot air welders, tarpaulin hot air welders, hot air welders, hand extrusion welders, and various welding tools, comprehensively meeting the diverse needs of both on-site construction and workshop operations.hot air welder roofing Our products have been exported to over 100 countries and have won the trust of more than 3,000 customers.plastic welding heat gun|super blog