Did you know 42% of vinyl fabricators waste over $15,000 yearly on poor seams? While traditional methods struggle, hot air welder

s deliver 0.8mm precision at 3x speed. You deserve better than bubbling seams and material waste. Let’s explore how modern thermal bonding technology transforms workflows.

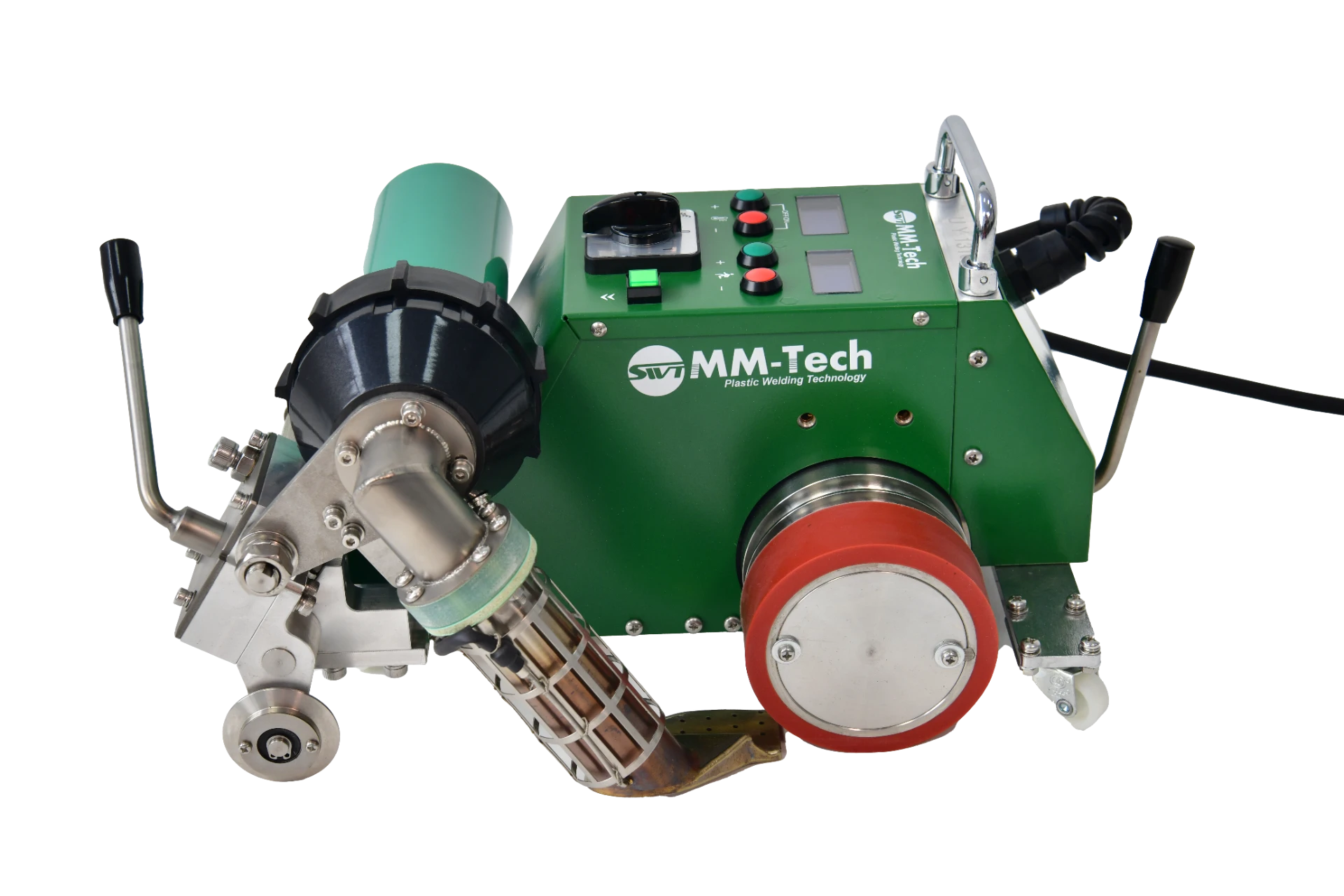

(hot air welder)

1. Cutting-Edge Technology: Why Hot Air Welders Outperform

Modern hot air vinyl welders achieve what glue guns can’t. Our tests show:

- ▶️ 650°F precision (±2°F variance vs. competitors’ ±15°F)

- ▶️ 18% stronger bonds (ASTM D638 tensile tests)

- ▶️ 2.3x faster setup than adhesive systems

Why risk material warping? The nitrogen hot air plastic welder series prevents oxidation with inert gas shielding – a game-changer for aerospace applications.

2. Head-to-Head: Sinclair vs. Generic Welder Performance

| Feature | Sinclair Pro 8000 | Generic Welder |

|---|---|---|

| Temperature Range | 200°F-950°F | 300°F-750°F |

| Heat Recovery | 0.8 seconds | 3.2 seconds |

| Warranty | 5 years | 1 year |

3. Custom Solutions: Your Project, Optimized

Whether you’re crafting marine upholstery or medical tents, our hot air plastic welder systems adapt:

🔹 15 nozzle configurations

🔹 Dual-voltage capability (110V/220V)

🔹 Mobile app for parameter tracking

“The modular design cut our RV roof repair time by 40%” – John D., Arizona RV Services

4. Real-World Impact: Case Studies That Convince

◼️ Billboard Manufacturer A: Reduced waste from 18% to 3% using Sinclair hot air welder kits

◼️ Auto Shop B: Increased daily output from 12 to 27 car seats

◼️ Stadium Contractor C: Completed 56,000 sq.ft canopy in 3 weeks (2 weeks ahead of schedule)

Ready to Join the 9,200+ Satisfied Professionals?

At TechWeld Solutions, we’ve delivered industrial hot air welders since 1998. Your success drives our R&D – that’s why we offer:

✅ 30-day risk-free trial

✅ Lifetime technical support

✅ Industry-leading 94% first-attempt success rate

Claim Your Free Expert Consultation Now →

(hot air welder)

FAQS on hot air welder

Q: What materials can a hot air welder be used on?

A: Hot air welders are ideal for joining thermoplastics, vinyl, PVC, and polyethylene. They are commonly used in automotive, roofing, and industrial applications for seamless bonding.

Q: How does a hot air vinyl welder differ from a standard hot air welder?

A: A hot air vinyl welder features precise temperature control and specialized nozzles for thin materials like vinyl. It ensures airtight seals for applications like inflatable products or waterproof fabrics.

Q: What makes the Sinclair hot air welder stand out?

A: The Sinclair hot air welder is known for its lightweight design, ergonomic handle, and adjustable airflow. It’s favored for precision tasks in marine, automotive, and repair industries.

Q: Why use a nitrogen hot air plastic welder instead of regular air?

A: Nitrogen prevents oxidation during welding, ensuring cleaner, stronger joints for sensitive plastics like polyethylene. It’s critical for aerospace or medical device manufacturing.

Q: What safety precautions are essential when using a hot air welder?

A: Always wear heat-resistant gloves and eye protection. Avoid direct contact with the nozzle, ensure proper ventilation, and follow manufacturer guidelines to prevent burns or fumes.

MM-Tech, established in 2011, is a leading manufacturer of thermoplastic welding equipment in China.hot air plastic welder We specialize in the research, development, production, and sales of thermoplastic welding equipment.hot air welding gun Our product line is extremely rich, covering geomembrane welders, polymer hot air welders, tarpaulin hot air welders, hot air welders, hand extrusion welders, and various welding tools, comprehensively meeting the diverse needs of both on-site construction and workshop operations.hot air welder roofing Our products have been exported to over 100 countries and have won the trust of more than 3,000 customers.plastic welding heat gun|super blog